Page 221 - Industrial Power Engineering and Applications Handbook

P. 221

Transmission of load and suitability of bearings 8/201

pumps, coal mill drives, conveyors, pulverizers and The couplings can be designed to develop torques

wagon tipplers. even higher than the Tpo of the motor. They can thus

Docks and harbours Material handling, mining, be made compatible for transmitting loads up to the

railway traction, process and chemical plants. optimum capacity of the motor and sustaining abnormal

load conditions without stalling or damage.

Most of these applications are heavy inertia loads and Basically a variable drive fluid coupling is a tailor-

require a light load start. The use of such variable drives made clutch to suit a specific load duty for more

can save energy. accurate application.

They are suitable for stepless speed variation and can

be controlled through speed, torque, temperature or

Advantages of variable-speed fluid couplings flow of a process. They can also be programmed for

any sequence of operation.

1 It is possible to switch the motor at no load by selecting Conventional throttling or damper control of flow is

a variable-speed fluid coupling. The oil need not be waste of energy. The use of such couplings can vary

prefilled which can be varied at site during operation speed through oil control, relieve strain on the system

as required. and save on the energy consumption.

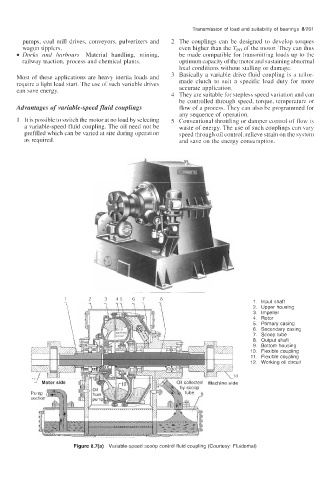

1. Input shaft

2. Upper housing

3. Impeller

4. Rotor

5. Primary casing

6. Secondary casing

7. Scoop tube

8. Output shaft

9. Bottom housing

10. Flexible coupling

11. Flexible coupling

12. Working oil circuit

Figure 8.7(a) Variable-speed scoop control fluid coupling (Courtesy: Fluidomat)