Page 222 - Industrial Power Engineering and Applications Handbook

P. 222

8/202 Industrial Power Engineering and Applications Handbook

8.4.2 Magnetic couplings and eddy current varied smoothly even up to 7-10% of N,. Similarly, the

couplings output speed can be maintained constant, even on a change

of load, by sensing the output speed and monitoring the

The principle of operation of these couplings is almost excitation level through a closed-loop speed feedback

the same as of fluid couplings except the air gap between control system. The speed can be sensed through a

the impeller and the runner of the coupling, which is tachogenerator mounted integrally on the load shaft. Very

now filled with iron granules or iron powder instead of accurate feedback control systems are also possible

fluid. The iron powder condenses into a solid mass when through microprocessor-based analogue and digital

magnetized through an external exciter. The exciter is controls, as discussed in Sections 6.6 and 13.2.3 to achieve

mounted on the same coupling, and clutches the runner total automation of speed, torque and power or any other

with the impeller. The power of transmission as well as process parameter such as, flow of liquid, gas or tem-

the speed of the runner can be controlled by varying the perature etc.

excitation. Figure 8.9(b) illustrates a general scheme to achieve

Eddy current couplings have become more common. speed control through such couplings. These couplings,

In this case the impeller of the coupling is a ferromagnetic up to 90 kW, are easily available.

drum, coupled to the induction motor and housed in an

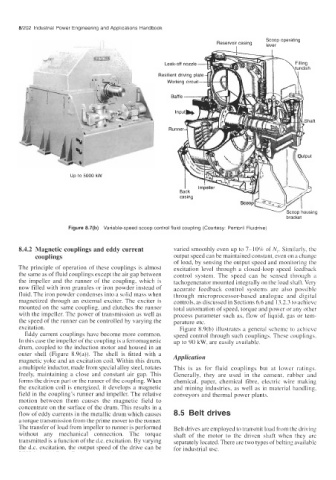

outer shell (Figure 8.9(a)). The shell is fitted with a Application

magnetic yoke and an excitation coil. Within this drum,

a multipole inductor, made from special alloy steel, rotates This is as for fluid couplings but at lower ratings.

freely, maintaining a close and constant air gap. This Generally, they are used in the cement, rubber and

forms the driven part or the runner of the coupling. When chemical, paper, chemical fibre, electric wire making

the excitation coil is energized, it develops a magnetic and mining industries, as well as in material handling,

field in the coupling’s runner and impeller. The relative conveyors and thermal power plants.

motion between them causes the magnetic field to

concentrate on the surface of the drum. This results in a

flow of eddy currents in the metallic drum which causes 8.5 Belt drives

a torque transmission from the prime mover to the runner.

The transfer of load from impeller to runner is performed Belt drives are employed to transmit load from the driving

without any mechanical connection. The torque shaft of the motor to the driven shaft when they are

transmitted is a function of the d.c. excitation. By varying separately located. There are two types of belting available

the d.c. excitation, the output speed of the drive can be for industrial use.