Page 412 - Industrial Power Engineering and Applications Handbook

P. 412

13/386 Industrial Power Engineering and Applications Handbook

periodically for any pitting or loosening. Such a the silver-plating is withered. Silver prevents

check is recommended at every six months of oxidation of copper contacts and also eliminates

operation and must be carried out meticulously, bimetallic corrosion.

particularly for aluminium busbar joints and cable

terminations. Aluminium is a highly malleable and Note

ductile metal and under high temperatures and Tarnishing (blackening) of contacts is a common characteristic of

pressures has a tendency to run out and loosen its silver-plated contacts. It is the formation of silver oxide film

grip. At locations that are critical, contaminated or which is a good conductor of heat and electricity is not a cause for

humid, or that are subject to vibrations, the period concern.

of maintenance checks may be reduced based on

experience. A logbook can also be maintained to - Clean and lubricate all the main incoming and

monitor the variance in important parameters and outgoing power contacts as well as the auxiliary

to take preventive measures during operation. sliding contacts at least once a year. Use of neutral

Draw-out components grease as noted in Section 13.6.l(iv) is recom-

- In a draw-out MCC all current-carrying compo- mended. A properly greased contact will also help

nents should be periodically checked for their to avoid a flashover.

silver-plating, proper contact area, spring pressure - For cleaning of contacts, use white petrol or carbon

and tightness of joints (this procedure can follow tetrachloride or perchloro-ethylene. Never use

the manufacturer’s maintenance schedule) or at sandpaper for it may damage the silver-coating

least during the six-monthly or yearly maintenance and also render the surface uneven which may

check ups of the busbars and the busbar joints as cause arcing and pitting during operation. While

noted above. The contacts or their springs may cleaning, care must be taken that the solvent does

be replaced when the contacts are worn out or not reach the insulating components.

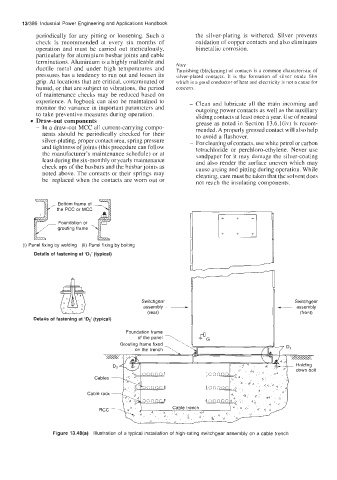

Bottom frame of

the PCC or MCC

Foundation or

grouting frame

(i) Panel fixing by welding (ii) Panel fixing by bolting

Details of fastening at ‘D,’ (typical)

A ---/----

Switchgear Switchgear

assembly - - assembly

(rear) (front)

Details of fastening at ‘D2’ (typical)

Foundation frame

of the panel \

Figure 13.48(a) Illustration of a typical installation of high-rating switchgear assembly on a cable trench