Page 66 - Industrial Power Engineering and Applications Handbook

P. 66

Motor torque, load torque and selection of motors 2/47

175

150

1 125

al

; 100

100

0.96T,

b?

75

50

35

25

Speed - ?

N,

torque

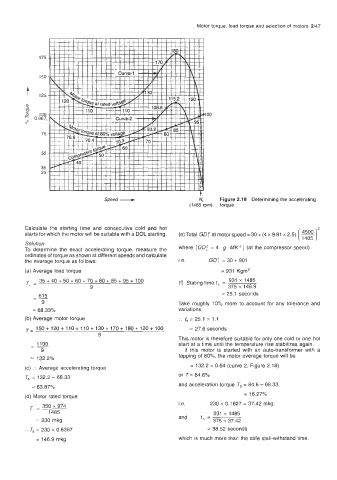

(1485 rpm) Figure 2.18 Determining the accelerating

Calculate the starting time and consecutive cold and hot

starts for which the motor will be suitable with a DOL starting. (e) Total GD: at motor speed = 30 + (4 x 9.81 x 2.5) ___

( ::::)z

Solution

To determine the exact accelerating torque, measure the where [GD: = 4. g. MK2] (at the compressor speed)

ordinates of torque as shown at different speeds and calculate

the average torque as follows: 1.e. GD: = 30 + 901

(a) Average load torque = 931 Kgm'

- 35+40+50+60+70+80+85+95+100 931 x 1485

i- (f) Stating time t, =

9 375 x 146.9

61 5

=- = 25.1 seconds

9 Take roughly 10% more to account for any tolerance and

= 68.33% variations,

(b) Average motor torque :. ts = 25.1 x 1.1

150+120+110+110+130+170+180+120+100 = 27.6 seconds

T=

9

This motor is therefore suitable for only one cold or one hot

=- 1190 start at a time until the temperature rise stabilizes again.

9 If this motor is started with an auto-transformer with a

2 132.2% tapping of 80%, the motor average torque will be

= 132.2 x 0.64 (curve 2, Figure 2.18)

(c) :. Average accelerating torque

or T= 84.6%

T, = 132.2 - 68.33

and acceleration torque T, = 84.6 - 68.33

= 63.87%

= 16.27%

(d) Motor rated torque

i.e. 230 x 0.1627 = 37.42 mkg.

- 350x974

I-

1485 931 x 1485

* 230 mkg and t, = 375 x 37.42

:. T, = 230 x 0.6387 = 98.52 seconds

= 146.9 mkg which is much more than the safe stall-withstand time.