Page 91 - Industrial Process Plant Construction Estimating and Man Hour Analysis

P. 91

Oil refinery Chapter 3 63

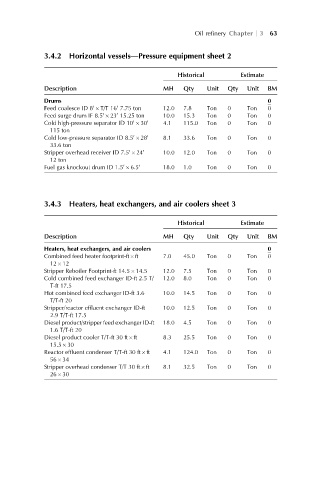

3.4.2 Horizontal vessels—Pressure equipment sheet 2

Historical Estimate

Description MH Qty Unit Qty Unit BM

Drums 0

Feed coalesce ID 8 T/T 16 7.75 ton 12.0 7.8 Ton 0 Ton 0

0

0

0

Feed surge drum IF 8.5 23 15.25 ton 10.0 15.3 Ton 0 Ton 0

0

Cold high-pressure separator ID 10 30 0 4.1 115.0 Ton 0 Ton 0

0

115 ton

Cold low-pressure separator ID 8.5 28 0 8.1 33.6 Ton 0 Ton 0

0

33.6 ton

Stripper overhead receiver ID 7.5 24 0 10.0 12.0 Ton 0 Ton 0

0

12 ton

Fuel gas knockout drum ID 1.5 6.5 0 18.0 1.0 Ton 0 Ton 0

0

3.4.3 Heaters, heat exchangers, and air coolers sheet 3

Historical Estimate

Description MH Qty Unit Qty Unit BM

Heaters, heat exchangers, and air coolers 0

Combined feed heater footprint-ft ft 7.0 45.0 Ton 0 Ton 0

12 12

Stripper Reboiler Footprint-ft 14.5 14.5 12.0 7.5 Ton 0 Ton 0

Cold combined feed exchanger ID-ft 2.5 T/ 12.0 8.0 Ton 0 Ton 0

T-ft 17.5

Hot combined feed exchanger ID-ft 3.6 10.0 14.5 Ton 0 Ton 0

T/T-ft 20

Stripper/reactor effluent exchanger ID-ft 10.0 12.5 Ton 0 Ton 0

2.9 T/T-ft 17.5

Diesel product/stripper feed exchanger ID-ft 18.0 4.5 Ton 0 Ton 0

1.6 T/T-ft 20

Diesel product cooler T/T-ft 30 ft ft 8.3 25.5 Ton 0 Ton 0

15.5 30

Reactor effluent condenser T/T-ft 30 ft ft 4.1 124.0 Ton 0 Ton 0

56 34

Stripper overhead condenser T/T 30 ft ft 8.1 32.5 Ton 0 Ton 0

26 30