Page 242 - Industrial Wastewater Treatment, Recycling and Reuse

P. 242

216 Industrial Wastewater Treatment, Recycling, and Reuse

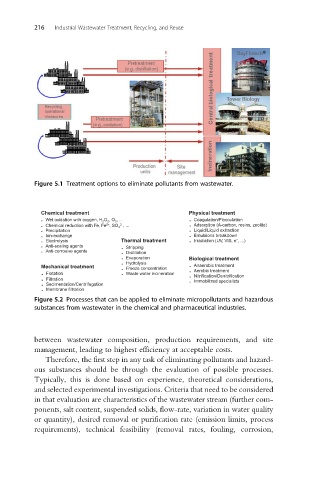

Figure 5.1 Treatment options to eliminate pollutants from wastewater.

Chemical treatment Physical treatment

. Wet oxidation with oxygen, H 2 O 2 , O 3 , ... . Coagulation/Flocculation

2+

2−

. Chemical reduction with Fe, Fe , SO 3 , ... . Adsorption (A-carbon, resins, zeolite)

. Precipitation . Liquid/Liquid extraction

. Ion-exchange . Emulsions breakdown

−

. Electrolysis Thermal treatment . Irradiation (UV, VIS, e , ...)

. Anti-scaling agents . Stripping

. Anti-corrosive agents . Distillation

. Evaporation Biological treatment

. Hydrolysis

Mechanical treatment . Freeze concentration . Anaerobic treatment

. Flotation . Waste water incineration . Aerobic treatment

. Nitrification/Denitrification

. Filtration . Immobilized specialists

. Sedimentation/Centrifugation

. Membrane filtration

Figure 5.2 Processes that can be applied to eliminate micropollutants and hazardous

substances from wastewater in the chemical and pharmaceutical industries.

between wastewater composition, production requirements, and site

management, leading to highest efficiency at acceptable costs.

Therefore, the first step in any task of eliminating pollutants and hazard-

ous substances should be through the evaluation of possible processes.

Typically, this is done based on experience, theoretical considerations,

and selected experimental investigations. Criteria that need to be considered

in that evaluation are characteristics of the wastewater stream (further com-

ponents, salt content, suspended solids, flow-rate, variation in water quality

or quantity), desired removal or purification rate (emission limits, process

requirements), technical feasibility (removal rates, fouling, corrosion,