Page 373 - Industrial Wastewater Treatment, Recycling and Reuse

P. 373

Phenolic Wastewater Treatment: Development and Applications of New Adsorbent Materials 345

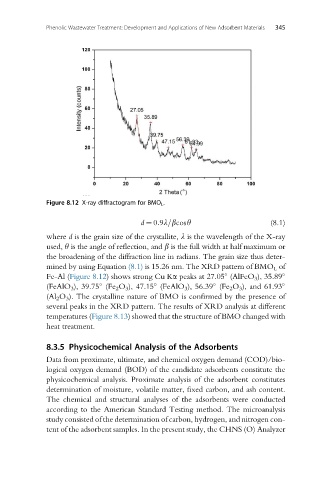

Figure 8.12 X-ray diffractogram for BMO L .

d ¼ 0:9l=bcosy (8.1)

where d is the grain size of the crystallite, l is the wavelength of the X-ray

used, y is the angle of reflection, and b is the full width at half maximum or

the broadening of the diffraction line in radians. The grain size thus deter-

mined by using Equation (8.1) is 15.26 nm. The XRD pattern of BMO L of

Fe-Al (Figure 8.12) shows strong Cu Ka peaks at 27.05 (AlFeO 3 ), 35.89

(FeAlO 3 ), 39.75 (Fe 2 O 3 ), 47.15 (FeAlO 3 ), 56.39 (Fe 2 O 3 ), and 61.93

(Al 2 O 3 ). The crystalline nature of BMO is confirmed by the presence of

several peaks in the XRD pattern. The results of XRD analysis at different

temperatures (Figure 8.13) showed that the structure of BMO changed with

heat treatment.

8.3.5 Physicochemical Analysis of the Adsorbents

Data from proximate, ultimate, and chemical oxygen demand (COD)/bio-

logical oxygen demand (BOD) of the candidate adsorbents constitute the

physicochemical analysis. Proximate analysis of the adsorbent constitutes

determination of moisture, volatile matter, fixed carbon, and ash content.

The chemical and structural analyses of the adsorbents were conducted

according to the American Standard Testing method. The microanalysis

study consisted of the determination of carbon, hydrogen, and nitrogen con-

tent of the adsorbent samples. In the present study, the CHNS (O) Analyzer