Page 404 - Industrial Wastewater Treatment, Recycling and Reuse

P. 404

376 Industrial Wastewater Treatment, Recycling, and Reuse

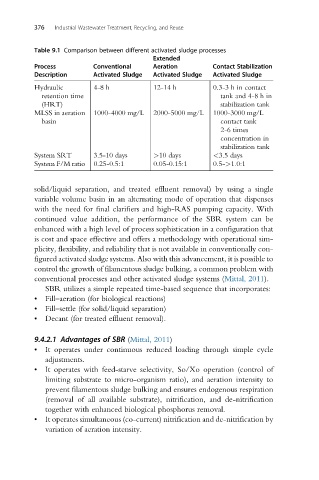

Table 9.1 Comparison between different activated sludge processes

Extended

Process Conventional Aeration Contact Stabilization

Description Activated Sludge Activated Sludge Activated Sludge

Hydraulic 4-8 h 12-14 h 0.3-3 h in contact

retention time tank and 4-8 h in

(HRT) stabilization tank

MLSS in aeration 1000-4000 mg/L 2000-5000 mg/L 1000-3000 mg/L

basin contact tank

2-6 times

concentration in

stabilization tank

System SRT 3.5-10 days >10 days <3.5 days

System F/M ratio 0.25-0.5:1 0.05-0.15:1 0.5->1.0:1

solid/liquid separation, and treated effluent removal) by using a single

variable volume basin in an alternating mode of operation that dispenses

with the need for final clarifiers and high-RAS pumping capacity. With

continued value addition, the performance of the SBR system can be

enhanced with a high level of process sophistication in a configuration that

is cost and space effective and offers a methodology with operational sim-

plicity, flexibility, and reliability that is not available in conventionally con-

figured activated sludge systems. Also with this advancement, it is possible to

control the growth of filamentous sludge bulking, a common problem with

conventional processes and other activated sludge systems (Mittal, 2011).

SBR utilizes a simple repeated time-based sequence that incorporates:

• Fill–aeration (for biological reactions)

• Fill–settle (for solid/liquid separation)

• Decant (for treated effluent removal).

9.4.2.1 Advantages of SBR (Mittal, 2011)

• It operates under continuous reduced loading through simple cycle

adjustments.

• It operates with feed-starve selectivity, So/Xo operation (control of

limiting substrate to micro-organism ratio), and aeration intensity to

prevent filamentous sludge bulking and ensures endogenous respiration

(removal of all available substrate), nitrification, and de-nitrification

together with enhanced biological phosphorus removal.

• It operates simultaneous (co-current) nitrification and de-nitrification by

variation of aeration intensity.