Page 85 - Inorganic Mass Spectrometry : Fundamentals and Applications

P. 85

~nductively Coupled Plasma Mass Spectrometry 75

size was too large was not directly known until recently. At the most commonly

used rate of sample delivery to the nebulizer (1 mllmin), only 1% to 3% of the

analyte enters the plasma. The rest (97% to 99%) goes down the drain. However,

as discussed later, the analyte transport efficiency increases as the sample uptake

rate delivered to the nebulizer decreases so that similar detection limits can be

obtained at 50 p,L/min as at 1 mL,/min [12].

A spray chamber also is necessary to limit the amount of solvent that enters

the ICP (less than about 20 p,L/min of aqueous aerosol and 30 mg/min of water

is

vapor). When water aerosol and vapor loading are higher, the plasma cooled and

molecular oxide formation increases.

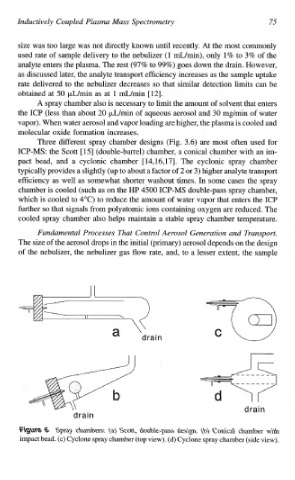

Three different spray chamber designs (Fig. 3.6) are most often used for

ICP-MS: the Scott [l51 (double-barrel) chamber, a conical chamber with an im-

pact bead, and a cyclonic chamber [ 14,16,17]. The cyclonic spray chamber

typically provides a slightly (up about a factor of 2 or 3) higher analyte transport

to

efficiency as well as somewhat shorter washout times. In some cases the spray

chamber is cooled (such as on the HP 4500 ICP-MS double-pass spray chamber,

which is cooled to 4°C) to reduce the amount of water vapor that enters the ICP

further so that signals from polyatomic ions containing oxygen are reduced. The

cooled spray chamber also helps maintain a stable spray chamber temperature.

~undamental Processes That Control Aerosol Generation and Transport.

The size of the aerosol drops in the initial (primary) aerosol depends on the design

of the nebulizer, the nebulizer gas flow rate, and, to a lesser extent, the sample

\'

drain

drain

drain

Spray chambers: (a) Scott, double-pass design. (b) Conical chamber with

impact bead. (c) Cyclone spray chamber (top view). (d) Cyclone spray chamber (side view).