Page 142 - Instrumentation Reference Book 3E

P. 142

126 Measurement of pressure

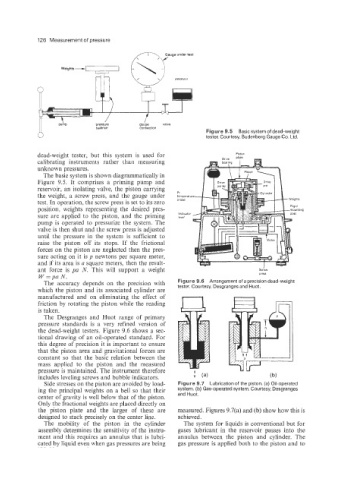

Figure 9.5 Basic system of dead-weight

tester. Courtesy, Budenberg Gauge Co. Ltd.

dead-weight tester, but this system is used for PlStO"

calibrating instruments rather than measuring

unknown pressures.

The basic system is shown diagrammatically in

Figure 9.5. It comprises a priming pump and

reservoir, an isolating valve, the piston carrying

the weight, a screw press, and the gauge under PI

ternperatu

test. In operation, the screw press is set to its zero probe

position, weights representing the desired pres-

sure are applied to the piston, and the priming Indicator

IkWC

pump is operated to pressurize the system. The

valve is then shut and the screw press is adjusted

until the pressure in the system is sufficient to

raise the piston off its stops. If the frictional

forces on the piston are neglected then the pres-

sure acting on it is p newtons per square meter,

and if its area is a square meters, then the result-

ant force is pa N. This will support a weight Screw

W =pa N. press

The accuracy depends on the precision with Figure 9.6 Arrangement of a precision dead-weight

which the piston and its associated cylinder are tester Courtesy, Desgranges and Huot

manufactured and on eliminating the effect of

friction by rotating the piston while the reading

is taken.

The Desgranges and Huot range of primary

pressure standards is a very refined version of

the dead-weight testers. Figure 9.6 shows a sec-

tional drawing of an oil-operated standard. For

this degree of precision it is important to ensure

that the piston area and gravitational forces are

constant so that the basic relation between the

mass applied to the piston and the measured

pressure is maintained. The instrument therefore

includes leveling screws and bubble indicators.

Side stresses on the piston are avoided by load- Figure 9.7 Lubrication of the piston. (a) Oil-operated

ing the principal weights on a bell so that their system. (b) Gas-operated system. Courtesy, Desgranges

center of gravity is well below that of the piston. and Huot.

Only the fractional weights are placed directly on

the piston plate and the larger of these are measured. Figures 9.7(a) and (b) show how this is

designed to stack precisely on the center line. achieved.

The mobility of the piston in the cylinder The system for liquids is conventional but for

assembly determines the sensitivity of the instru- gases lubricant in the reservoir passes into the

ment and this requires an annulus that is lubri- annulus between the piston and cylinder. The

cated by liquid even when gas pressures are being gas pressure is applied both to the piston and to