Page 146 - Instrumentation Reference Book 3E

P. 146

130 Measurement of pressure

High pressure diaphragm

(Do not remove)

Range spring nut

pressure diaphragm

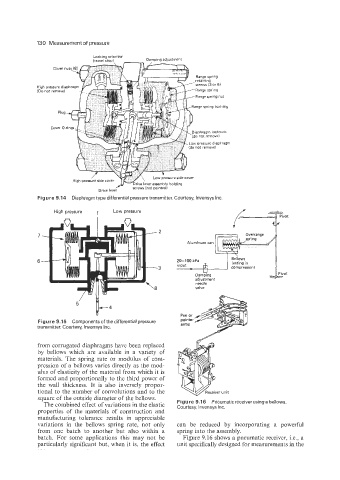

Figure 9.14 Diaphragm type differential pressure transmitter Courtesy, lnvensys Inc

High pressure 1 Low pressure

I

Aluminum can

I \

Beliows

20-100 kPa lacting in

input compression)

U

1 Pivot

Damping =w+7,?,

adjustment

needle

valve

5 ’ k4

pointer

Figure 9.15 Components of the differential pressure Pen or

arms

transmitter. Courtesy, lnvensys Inc.

from corrugated diaphragms have been replaced

by bellows which are available in a variety of

materials. The spring rate or modulus of com-

pression of a bellows varies directly as the mod-

ulus of elasticity of the material from which it is

formed and proportionally to the third power of

the wall thickness. It is also inversely propor-

tional to the number of convolutions and to the er unit

square of the outside diameter of the bellows.

The combined effect of variations in the elastic Figure 9.1 6 Pneumatic receiver using a bellows.

Courtesy, lnvensys Inc.

properties of the materials of construction and

manufacturing tolerance results in appreciable

variations in the bellows spring rate, not only can be reduced by incorporating a powerful

from one batch to another but also within a spring into the assembly.

batch. For some applications this may not be Figure 9.16 shows a pneumatic receiver, Le., a

particularly significant but, when it is, the effect unit specifically designed for measurements in the