Page 148 - Instrumentation Reference Book 3E

P. 148

132 Measurement of pressure

balanced when the input differential pressure is in both sensitivity and resolution as well as provid-

zero. The subsequent application of a differential ing means for compensating for nonlinear effects.

pressure changes the capacitances of the electrodes One of the devices in which these techniques have

which unbalances the bridge network. The out-of- been applied is the capacitance manometer shown

balance signal is amplified and converted into diagrammatically in Figure 9.20.

either a 0-1OV d.c. or a 420mA output signal. For such a sensor it is important that the dia-

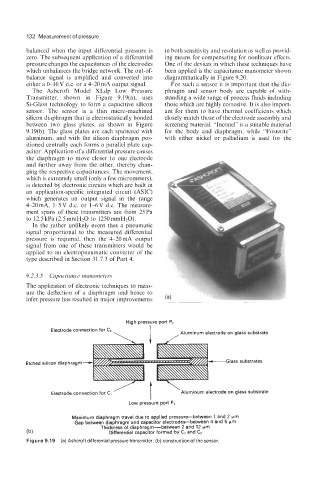

The Ashcroft Model XLdp Low Pressure phragm and sensor body are capable of with-

Transmitter, shown in Figure 9.19(a), uses standing a wide range of process fluids including

Si-Glass technology to form a capacitive silicon those which are highly corrosive. It is also import-

sensor. The sensor is a thin micro-machined ant for them to have thermal coefficients which

silicon diaphragm that is electrostatically bonded closely match those of the electrode assembly and

between two glass plates, as shown in Figure screening material. “Inconel” is a suitable material

9.19(b). The glass plates are each sputtered with for the body and diaphragm, while “Fosterite”

aluminum, and with the silicon diaphragm pos- with either nickel or palladium is used for the

itioned centrally each forms a parallel plate cap-

acitor. Application of a differential pressure causes

the diaphragm to move closer to one electrode

and further away from the other, thereby chan-

ging the respective capacitances. The movement,

which is extremely small (only a few micrometers),

is detected by electronic circuits which are built in

an application-specific integrated circuit (ASIC)

which generates an output signal in the range

420mA, 1-5V d.c. or 14V d.c. The measure-

ment spans of these transmitters are from 25Pa

to 12.5 kPa (2.5mmHzO to 1250mmHzO).

In the rather unlikely event that a pneumatic

signal proportional to the measured differential i

pressure is required, then the 4-20 mA output

signal from one of these transmitters would be

applied to an electropneumatic converter of the

type described in Section 31.7.3 of Part 4.

Ir

9.2.3.5 Capacitance manorneters

The application of electronic techniques to meas-

ure the deflection of a diaphragm and hence to

infer pressure has resulted in major improvements

High pressure port P2

Electrode connection for c2 I ,Aluminum electrode on glass substrate

\

’ I ‘Aluminum electrode on glass substrate

Electrode connection for Cl

Low pressure port PI

Maximum diaphragm travel due to applied pressurdetween 1 and 2 pm

Gap between diaphragm and capacitor electrodes-between 4 and 5 pm

Thickness of diaphragm-between 2 and 12 pm

(b) Differential capacitor formed by C1 and C2

Figure 9.19 (a) Ashcroft differential pressure transmitter; (b) construction of the sensor.