Page 151 - Instrumentation Reference Book 3E

P. 151

Pressure measurement 135

The mechanical strength of silicon depends

largely on the state of the surface and in genera1

this imposes an upper limit of about 100 MPa on

the pressures that can be measured safely by the

sensors. The lower limit is about 2OkPa and is

determined by the minimum thickness to which

the diaphragm can be manufactured reliably.

Both the gauge factor G and resistance R of the

diffused resistors are sensitive to changes of tem-

perature, and the sensors need to be associated

with some form of compensating circuits. In some

instances this is provided by discrete resistors

closely associated with the gauge itself. Others

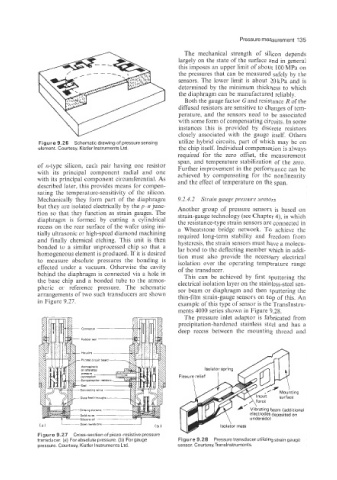

Figure 9.26 Schematic drawing of pressure sensing utilize hybrid circuits, part of which may be on

element. Courtesy, Kistler Instruments Ltd. the chip itself. Individual compensation is always

required for the zero offset, the measurement

span, and temperature stabilization of the zero.

of n-type silicon, each pair having one resistor Further improvement in the performance can be

with its principal component radial and one achieved by compensating for the nonlinearity

with its principal component circumferential. As and the effect of temperature on the span.

described later, this provides means for compen-

saiing the temperature-sensitivity of the silicon.

Mechanically they form part of the diaphragm 9.2.4.2 Strain gauge pressarre semm

but they are isolated electrically by the p-n junc- Another group of pressure sensors is based on

tion so that they function as strain gauges. The strain-gauge technology (see Chapter 4), in which

diaphragm is formed by cutting a cylindrical the resistance-type strain senscrs are connected in

recess on the rear surface of the wafer using ini- a Wheatstone bridge network. To achieve the

tially ultrasonic or high-speed diamond machining required long-term stability and freedom from

and finally chemical etching. This unit is then hysteresis, the strain sensors must have a molecu-

bonded to a similar unprocessed chip so that a lar bond to the deflecting inember which in addi-

hcmogeneous element is produced. If it is desired tion must also provide the necessary electrical

to measure absolute pressures the bonding is isolation over the operating temperature range

effected mder a vacuum. Otherwise the cavity of the transducer.

behind the diaphragm is connected via a hole in This can be achieved by first sputtering the

the base chip and a bonded tube to the atmos- electrical isolation layer on the stainless-steel sen-

pheric or reference pressure. The schematic sor beam or diaphragm and then sputtering the

arrangements of two such transducers are shown thin-film strain-gauge sensors on top of this. An

in Figure 9.27. example of this type of sensor is the TransInstru-

ments 4000 series shown in Figure 9.28.

The pressure inlet adaptor is fabricated from

precipitation-hardened stainless steel and has a

deep recess between the mounting thread and

electrod& deposited on

7 underside)

-Sreel membrane r Isolator mass

Figure 9.27 Cross-section of piezo-resistive pressure

transducer. (a) For absolute pressure. (b) For gauge Figure 9.28 Pressure transducer utilizing strain gauge

pressure. Courtesy, Kistler Instruments Ltd. sensor. Courtesy,Translnstrumen?s.