Page 155 - Instrumentation Reference Book 3E

P. 155

Pressure transmitters 139

Conti ’0 I

I=-

relay

output

Element

Figure 9.33 Arrangement of pneumatic motion-balance

transmitter. Courtesy, lnvensys Inc.

or temperature in the case of a filled thermal

system, cause the free end of the Bourdon tube

to move. This movement is transmitted via a &- Applied force

linkage to the lever that pivots about the axis A. Figure 9.34 Arrangement of pneumatic force-balance

The free end of this lever bears on a second lever transmitter. Courtesy, lnvensys Inc.

that is pivoted at its center so that the movement

is thus transmitted to a third lever that is free to force bar where it is transmitted via the flexure

pivot about the axis C. The initial movement is connector to the top of the range rod. If the

to the flapper Of the flapper/nozz1e applied force causes movement to the right, the

system. If; as a resu1t; the gap between the flapper flapper uncovers the nozzle with the result that the

and nozzle is increased, the nozzle back-pressure nozzle back-pressure falls. This &ange is magni-

falls and this in turn causes the output pressure fied by the “relay,, whose output is appiied to the

from the to As this pressure is feedback bellows thereby producing a force which

applied to the bellows the change causes the lever balances the force applied initially, The output

pivoted about the axis B to retract so that the signal is taken from the “relay9, and by varying

lever pivoted about the axis the flapper the setting of the range wheel, the sensitivity or

towards the nozzle. This causes the nozzle back- span can be adjusted through a range of about

pressure to rise until equilibrium is established. to By varying the primary element pressures

For each Of the measurement there is a from about 1.3kPa to 85Mpa, differential pres-

definite flapperhozzle relationship and therefore sures from kpa to 14 MPa may be measured,

a definite output signal. Figures 9.35-9.38 show some of the alternative

primary elements which can be used in conjunction

9.3.2 Pneumatic force-balance pressure

transmitters

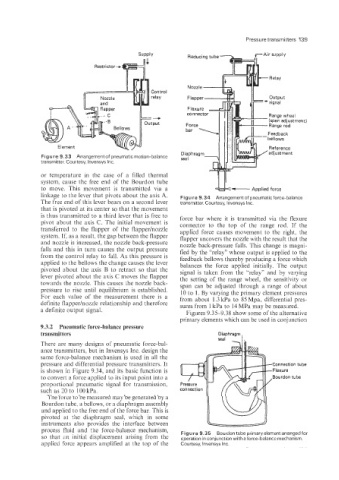

There are many designs of pneumatic force-bal-

ance transmitters, but in Invensys Inc. design the

same force-balance mechanism is used in all the

pressure and differential pressure transmitters. It Connection tube

is shown in Figure 9.34, and its basic function is Flexure

to convert a force applied to its input point into a Bourdon tube

proportional pneumatic signal for transmission, Pr

such as 20 to 100 kPa.

The force to be measured may be generated by a

Bourdon tube, a bellows, or a diaphragm assembly

and applied to the free end of the force bar. This is

pivoted at the diaphragm seal; which in some

instruments also provides the interface between

process fluid and the force-ba1ance mechanism, Figure 9.35 Bourdon tube primaryelement arranged for

SO that Bn initial displacement arising from the operation in conjunction with a force-balance mechanism,

applied force appears amplified at the top of the Courtesy, Invensys Inc.