Page 154 - Instrumentation Reference Book 3E

P. 154

138 Measurement of pressure

fork temperature

sensor

Input pressure

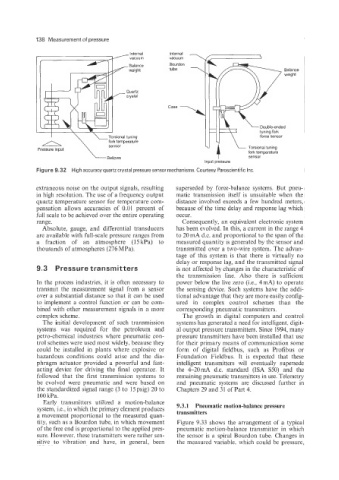

Figure 9.32 High accuracy quartz crystal pressure sensor mechanisms. Courtesy Paroscientific Inc

extraneous noise on the output signals, resulting superseded by force-balance systems. But pneu-

in high resolution. The use of a frequency output matic transmission itself is unsuitable when the

quartz temperature sensor for temperature com- distance involved exceeds a few hundred meters,

pensation allows accuracies of 0.01 percent of because of the time delay and response lag which

full scale to be achieved over the entire operating occur.

range. Consequently, an equivalent electronic system

Absolute, gauge, and differential transducers has been evolved. In this, a current in the range 4

are available with full-scale pressure ranges from to 20 mA d.c. and proportional to the span of the

a fraction of an atmosphere (15kPa) to measured quantity is generated by the sensor and

thousands of atmospheres (276 MPa). transmitted over a two-wire system. The advan-

tage of this system is that there is virtually no

delay or response lag, and the transmitted signal

9.3 Pressure transmitters is not affected by changes in the characteristic of

the transmission line. Also there is sufficient

In the process industries, it is often necessary to power below the live zero (Le., 4mA) to operate

transmit the measurement signal from a sensor the sensing device. Such systems have the addi-

over a substantial distance so that it can be used tional advantage that they are more easily config-

to implement a control function or can be com- ured in complex control schemes than the

bined with other measurement signals in a more corresponding pneumatic transmitters.

complex scheme. The growth in digital computers and control

The initial development of such transmission systems has generated a need for intelligent, digit-

systems was required for the petroleum and al output pressure transmitters. Since 1994, many

petro-chemical industries where pneumatic con- pressure transmitters have been installed that use

trol schemes were used most widely, because they for their primary means of communication some

could be installed in plants where explosive or form of digital fieldbus, such as Profibus or

hazardous conditions could arise and the dia- Foundation Fieldbus. It is expected that these

phragm actuator provided a powerful and fast- intelligent transmitters will eventually supersede

acting device for driving the final operator. It the 4-2OmA d.c. standard (ISA S50) and the

followed that the first transmission systems to remaining pneumatic transmitters in use. Telemetry

be evolved were pneumatic and were based on and pneumatic systems are discussed further in

the standardized signal range (3 to 15psig) 20 to Chapters 29 and 31 of Part 4.

100 kPa.

Early transmitters utilized a motion-balance

system, i.e., in which the primary element produces 9.3.1 Pneumatic motion-balance pressure

transmitters

a movement proportional to the measured quan-

tity, such as a Bourdon tube, in which movement Figure 9.33 shows the arrangement of a typical

of the free end is proportional to the applied pres- pneumatic motion-balance transmitter in which

sure. However, these transmitters were rather sen- the sensor is a spiral Bourdon tube. Changes in

sitive to vibration and have, in general, been the measured variable, which could be pressure,