Page 149 - Instrumentation Reference Book 3E

P. 149

Pressure measurement 133

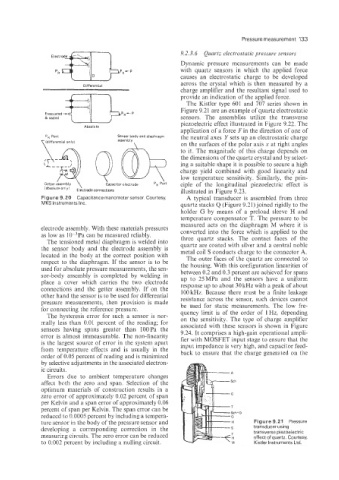

9.2.3.6 Quartz electrostatic pressure sensors

Dynamic pressure measurements can be made

with quartz sensors in which the applied force

causes an electrostatic charge to be developed

across the crystal which is then measured by a

Differential

charge amplifier and the resultant signal used to

provide an indication of the applied force.

The Kistler type 601 and 707 series shown in

Figure 9.21 are an example of quartz electrostatic

sensors. The assemblies utilize the transverse

piezoelectric effect illustrated in Figure 9.22. The

Absolute

application of a force Fin the direction of one of

PR Port Sensor body and diaphragm the neutral axes Y sets up an electrostatic charge

yldifferential only) assembly

\ on the surfaces of the polar axis x at right angles

to it. The magnitude of this charge depends on

the dimensions of the quartz crystal and by select-

ing a suitable shape it is possible to secure a high

charge yield combined with good linearity and

low temperature sensitivity. Similarly, the prin-

ciple of the longitudinal piezoelectric effect is

iabsolute Only' Elictrode connections illustrated in Figure 9.23.

Figure 9.20 Capacitance manometer sensor. Courtesy, A typical transducer is assembled from three

MKS Instruments Inc. quartz stacks Q (Figure 9.21) joined rigidly to the

holder G by means of a preload sleeve H and

temperature compensator T. The pressure to be

measured acts on the diaphragm M where it is

electrode assembly. With these materials pressures converted into the force which is applied to the

as low as 10-3Pa can be measured reliably. three quartz stacks. The contact faces of the

The tensioned metal diaphragm is welded into

the sensor body and the electrode assembly is quartz are coated with silver and a central noble

metal coil S conducts charge to the connector A.

located in the body at the correct position with The outer faces of the quartz are connected to

respect to the diaphragm. If the sensor is to be the housing. With this confignration linearities of

used for absolute pressure measurements, the sen- between 0.2 and 0.3 percent are achieved for spans

sor-body assembly is completed by welding in up to 25MPa and the sensors have a uniforn;

place a cover which carries the two electrode

connections and the getter assembly. If on the response up to about 30 lcHz with a peak of about

100 kHz. Because there Eust be a finite leakage

other hand the sensor is to be used for differential

pressure measurements, then provision is made resistance across the sensor, such devices cannot

for connecting the reference pressure. be used for static measurements. The low fre-

quency limit is of the order of 1 Hz. depending

The hysteresis error for such a sensor is nor-

mally less than 0.01 percent of the reading: for on the sensitivity. The type of charge amplifier

associated with these sensors is shown in Figure

sensors having spans greater than l0OPa the

error is almost immeasurable. The non-linearity 9.24. It comprises a high-gain operational ampli-

fier with MOSFET input stage to ensure that the

is the largest source of error in the system apart input impedance is very high, and capacitor feed-

from temperature effects and is usually in the back to ensure that the charge generated 011 the

order of 0.05 percent of reading and is minimized

by selective adjustments in the associated electron-

ic circuits.

Errors due io ambient temperature changes

affect both the zero and span. Selection of the

optimum materials of construction results in a

zero error of approximately 0.02. percent of span

per Kelvin and a span error of approximately 0.06

percent of span per Kelvin. The span error can be

reduced to 0.0005 percent by including a tempera- SchiD

0

ture sensor in the body of the pressure sensor and H Figure 9.21 Pressure

developing a corresponding correction in the transducer using

transverse piezoelectric

measuricg circuits. The zero error can be reduced effect of quartz. Courtesy,

to 0.002 percent by including a nulling circuit. Kistler Instruments Ltd.