Page 147 - Instrumentation Reference Book 3E

P. 147

Pressure measurement 131

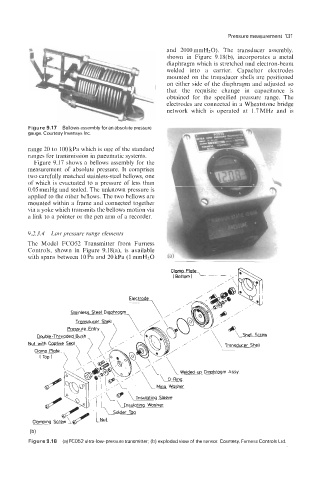

and 2000 mmH20). The transducer assembly,

shown in Figure 9.18(b), incorporates a metal

diaphragm which is stretched and electron-beam

welded into a carrier. Capacitor electrodes

mounted on the transducer shells are positioned

on either side of the diaphragm and adjusted so

that the requisite change in capacitance is

obtained for the specified pressure range. The

electrodes are connected in a Wheatstone bridge

network which is operated at 1.7MHz and is

*’

Figure 9.17 Bellows assembly for an absolute pressure

gauge. Courtesy lnvensys Inc.

range 20 to 100 kPa which is one of the standard

ranges for transmission in pneumatic systems.

Figure 9.17 shows a bellows assembly for the

measurement of absolute pressure. It comprises

two carefully matched stainless-steel bellows, one

of which is evacuated to a pressure of less than

0.05 mmHg and sealed. The unknown pressure is

applied to the other bellows. The two bellows are

mounted within a frame and connected together

via a yoke which transmits the bellows motion via

a link to a pointer or the pen arm of a recorder.

9.2.3.4 Low pressure range elements

The Model FC052 Transmitter from Furness

Controls, shown in Figure 9.18(a), is available

with spans between lOPa and 20kPa (1 mmH2O

p Diaphragm Assy

(b)

Figure 9.1 8 (a) FC052 ultra-low-pressure transmitter, (b) exploded view of the sensor Courtesy, Furness Controls Ltd