Page 312 - Instrumentation Reference Book 3E

P. 312

296 Temperature measurement

Pipe wall

-Shield

I

I Measured

I

I

Set pint

L __________-_ _------ ----

I

Figure 14.64 Radiation shield for gas temperature

measurement. Controller

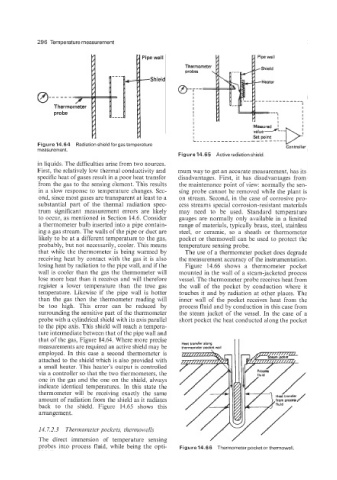

Figure 14.65 Active radiation shield.

in liquids. The difficulties arise from two sources.

First, the relatively low thermal conductivity and mum way to get an accurate measurement, has its

specific heat of gases result in a poor heat transfer disadvantages. First. it has disadvantages from

from the gas to the sensing element. This results the maintenance point of view: normally the sen-

in a slow response to temperature changes. Sec- sing probe cannot be removed while the plant is

ond, since most gases are transparent at least to a on stream. Second, in the case of corrosive pro-

substantial part of the thermal radiation spec- cess streams special corrosion-resistant materials

trum significant measurement errors are likely may need to be used. Standard temperature

to occur, as mentioned in Section 14.6. Consider gauges are normally only available in a limited

a thermometer bulb inserted into a pipe contain- range of materials, typically brass, steel, stainless

ing a gas stream. The walls of the pipe or duct are steel, or ceramic, so a sheath or thermometer

likely to be at a different temperature to the gas, pocket or thei-mowell can be used to protect the

probably, but not necessarily, cooler. This means temperature sensing probe.

that while the thermometer is being warmed by The use of a thermometer pocket does degrade

receiving heat by contact with the gas it is also the measurement accuracy of the instrumentation.

losing heat by radiation to the pipe wall, and if the Figure 14.66 shows a thermometer pocket

wall is cooler than the gas the thermometer will mounted in the wall of a steam-jacketed process

lose more heat than it receives and will therefore vessel. The thermometer probe receives heat from

register a lower temperature than the true gas the wall of the pocket by conduction where it

temperature. Likewise if the pipe wall is hotter touches it and by radiation at other places. The

than the gas then the thermometer reading will inner wall of the pocket receives heat from the

be too high. This error can be reduced by process fluid and by conduction in this case from

surrounding the sensitive part of the thermometer the steam jacket of the vessel. In the case of a

probe with a cylindrical shield with its axis parallel short pocket the heat conducted along the pocket

to the pipe axis. This shield will reach a tempera-

ture intermediate between that of the pipe wall and

that of the gas, Figure 14.64. Where more precise

measurements are required an active shield may be Heat transfer along

employed. In this case a second thermometer is

attached to the shield which is also provided with

a small heater. This heater’s output is controlled

via a controller so that the two thermometers, the

one in the gas and the one on the shield, always

indicate identical temperatures. In this state the

thermometer will be receiving exactly the same

amount of radiation from the shield as it radiates

back to the shield. Figure 14.65 shows this

arrangement.

14.7.2.3 Tlzennonzeteu pockets, thernzowells

The direct immersion of temperature sensing

probes into process fluid, while being the opti- Figure 14.66 Thermometer pocket or thermowell.