Page 568 - Instrumentation Reference Book 3E

P. 568

550 Measurements employing nuclear techniques

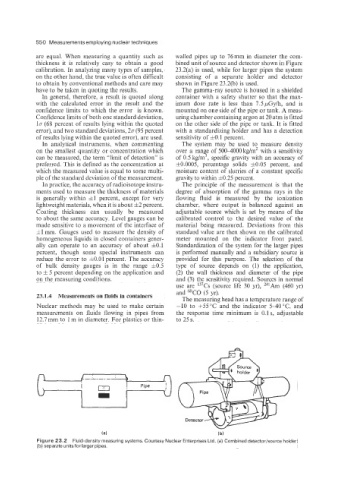

are equal. When measuring a quantity such as walled pipes up to 76mm in diameter the com-

thickness it is relatively easy to obtain a good bined unit of source and detector shown in Figure

calibration. In analyzing many types of samples, 23.2(a) is used, while for larger pipes the system

on the other hand, the true value is often difficult consisting of a separate holder and detector

to obtain by conventional methods and care may shown in Figure 23.2(b) is used.

have to be taken in quoting the results. The gamma-ray source is housed in a shielded

In general. therefore, a result is quoted along container with a safety shutter so that the max-

with the calculated error in the result and the imum dose rate is less than 7.5pGy/h, and is

confidence limits to which the error is known. mounted on one side of the pipe or tank. A meas-

Confidence limits of both one standard deviation, uring chamber containing argon at 20 atm is fitted

la (68 percent of results lying within the quoted on the other side of the pipe or tank. It is fitted

error), and two standard deviations, 2a (95 percent with a standardizing holder and has a detection

of results lying within the quoted error), are used. sensitivity of kO.1 percent.

In analytical instruments, when commenting The system may be used to measure density

on the smallest quantity or concentration which over a ran e of 5004000 kg/m2 with a sensitivity

5

can be measured, the term “limit of detection” is of 0.5 kg/m . specific gravity with an accuracy of

preferred. This is defined as the concentration at f0.0005, percentage solids &0.05 percent, and

which the measured value is equal to some multi- moisture content of slurries of a constant specific

ple of the standard deviation of the measurement. gravity to within h0.25 percent.

In practice, the accuracy of radioisotope instru- The principle of the measurement is that the

ments used to measure the thickness of materials degree of absorption of the gamma rays in the

is generally within *I percent, except for very flowing fluid is measured by the ionization

lightweight materials, when it is about 1t2 percent. chamber, where output is balanced against an

Coating thickness can usually be measured adjustable source which is set by means of the

to about the same accuracy. Level gauges can be calibrated control to the desired value of the

made sensitive to a movement of the interface of material being measured. Deviations from this

klmm. Gauges used to measure the density of standard value are then shown on the calibrated

homogeneous liquids in closed containers gener- meter mounted on the indicator front panel.

ally can operate to an accuracy of about hO.l Standardization of the system for the larger pipes

percent, though some special instruments can is performed manually and a subsidiary source is

reduce the error to kO.01 percent. The accuracy provided for this purpose. The selection of the

of bulk density gauges is in the range 3~0.5 type of source depends on (1) the application,

to f 5 percent depending on the application and (2) the wall thickness and diameter of the pipe

on the measuring conditions. and (3) the sensitivity required. Sources in normal

use are 137Cs (source life 30 yr), 241Am (460 yr)

and 6oC0 (5 yr).

23.1.4 Measurements on fluids in containers

The measuring head has a temperature range of

Nuclear methods may be used to make certain -10 to +55”C and the indicator 540”C, and

measurements on fluids flowing in pipes from the response time minimum is 0.1 s, adjustable

11.7mm to 1 m in diameter. For plastics or thin- to 25 s.

(a)

Figure 23.2 Fluid-density measuring systems. Courtesy Nuclear Enterprises Ltd. (a) Combined detector/source holder;

(b) separate units for larger pipes.