Page 107 - Sami Franssila Introduction to Microfabrication

P. 107

86 Introduction to Microfabrication

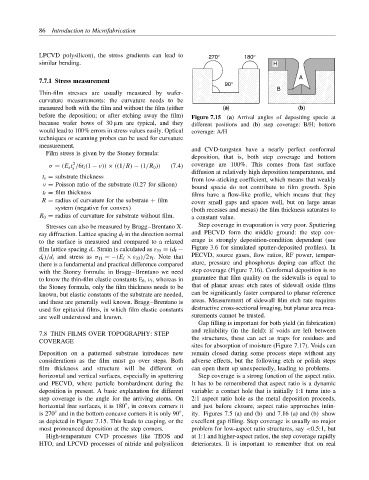

LPCVD polysilicon), the stress gradients can lead to 270° 180°

similar bending. H

A

7.7.1 Stress measurement

90°

B

Thin-film stresses are usually measured by wafer-

curvature measurements: the curvature needs to be

measured both with the film and without the film (either (a) (b)

before the deposition; or after etching away the film) Figure 7.15 (a) Arrival angles of depositing specie at

because wafer bows of 30 µm are typical, and they different positions and (b) step coverage: B/H; bottom

would lead to 100% errors in stress values easily. Optical coverage: A/H

techniques or scanning probes can be used for curvature

measurement.

Film stress is given by the Stoney formula: and CVD-tungsten have a nearly perfect conformal

deposition, that is, both step coverage and bottom

2

σ = (E s t /6t f (1 − ν)) × ((1/R) − (1/R 0 )) (7.4) coverage are 100%. This comes from fast surface

s

diffusion at relatively high deposition temperatures, and

t s = substrate thickness

from low-sticking coefficient, which means that weakly

ν = Poisson ratio of the substrate (0.27 for silicon) bound specie do not contribute to film growth. Spin

t f = film thickness films have a flow-like profile, which means that they

R = radius of curvature for the substrate + film cover small gaps and spaces well, but on large areas

system (negative for convex) (both recesses and mesas) the film thickness saturates to

R 0 = radius of curvature for substrate without film. a constant value.

Stresses can also be measured by Bragg–Brentano X- Step coverage in evaporation is very poor. Sputtering

ray diffraction. Lattice spacing d f in the direction normal and PECVD form the middle ground: the step cov-

to the surface is measured and compared to a relaxed erage is strongly deposition-condition dependent (see

film lattice spacing d r . Strain is calculated as ε 33 = (d f − Figure 3.6 for simulated sputter-deposited profiles). In

d r )/d r and stress as σ 11 = −(E f × ε 33 )/2ν f . Note that PECVD, source gases, flow ratios, RF power, temper-

there is a fundamental and practical difference compared ature, pressure and phosphorus doping can affect the

with the Stoney formula: in Bragg–Brentano we need step coverage (Figure 7.16). Conformal deposition is no

to know the thin-film elastic constants E f , ν f , whereas in guarantee that film quality on the sidewalls is equal to

the Stoney formula, only the film thickness needs to be that of planar areas: etch rates of sidewall oxide films

known, but elastic constants of the substrate are needed, can be significantly faster compared to planar reference

and these are generally well known. Bragg–Brentano is areas. Measurement of sidewall film etch rate requires

used for epitaxial films, in which film elastic constants destructive cross-sectional imaging, but planar area mea-

are well understood and known. surements cannot be trusted.

Gap filling is important for both yield (in fabrication)

and reliability (in the field): if voids are left between

7.8 THIN FILMS OVER TOPOGRAPHY: STEP

COVERAGE the structures, these can act as traps for residues and

sites for absorption of moisture (Figure 7.17). Voids can

Deposition on a patterned substrate introduces new remain closed during some process steps without any

considerations as the film must go over steps. Both adverse effects, but the following etch or polish steps

film thickness and structure will be different on can open them up unexpectedly, leading to problems.

horizontal and vertical surfaces, especially in sputtering Step coverage is a strong function of the aspect ratio.

and PECVD, where particle bombardment during the It has to be remembered that aspect ratio is a dynamic

deposition is present. A basic explanation for different variable: a contact hole that is initially 1:1 turns into a

step coverage is the angle for the arriving atoms. On 2:1 aspect ratio hole as the metal deposition proceeds,

horizontal free surfaces, it is 180 , in convex corners it and just before closure, aspect ratio approaches infin-

◦

◦

is 270 and in the bottom concave corners it is only 90 , ity. Figures 7.5 (a) and (b) and 7.16 (a) and (b) show

◦

as depicted in Figure 7.15. This leads to cusping, or the excellent gap filling. Step coverage is usually no major

most pronounced deposition at the step corners. problem for low-aspect ratio structures, say <0.5:1, but

High-temperature CVD processes like TEOS and at 1:1 and higher-aspect ratios, the step coverage rapidly

HTO, and LPCVD processes of nitride and polysilicon deteriorates. It is important to remember that on real