Page 106 - Sami Franssila Introduction to Microfabrication

P. 106

Thin-film Growth and Structure 85

Wafers are ca. 1000 times thicker than films, and high-temperature anneal will result in tensile stress

because all solids have similar elastic constants, wafer (Figure 7.13).

stresses and strains are ca. 1000 times less than those of Bimetal thermometer is a classic example of a thermal

thin films. Thin-film stresses are of the order of 10 to expansion coefficient mismatch. Bimorph structures can

2

1000 MPa (1000 MPa = 10 10 dyn/cm ). be used as sensors and actuators in microsystems, but the

Annealing temperature can be used to tailor stresses: initial shape has to be known. Shown in Figure 7.14 are

a long-time, low-temperature anneal of fine-grained SiO 2 /Al and SiO 2 /Ti cantilevers, which are bent because

LPCVD silicon (deposited at 580 C) will result of stresses in the structures, without external sensing

◦

in a slightly compressively stressed film, while or actuation force. In a single material cantilever (e.g.,

0.004 700°C 650°C

0.003

Tension 0.002 850°C 950°C

0.001

ο

1050 c

0

30 60 90 120 150 180

−0.001 Time (min)

−0.002 Anneal curves

Compression −0.003 for polysilicon

−0.004

−0.005 Strain vs time

−0.006 600°C

−0.007

◦

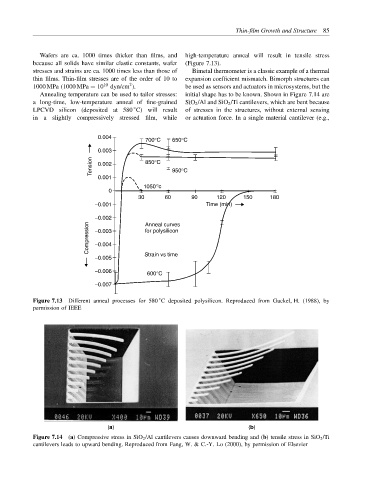

Figure 7.13 Different anneal processes for 580 C deposited polysilicon. Reproduced from Guckel, H. (1988), by

permission of IEEE

(a) (b)

Figure 7.14 (a) Compressive stress in SiO 2 /Al cantilevers causes downward bending and (b) tensile stress in SiO 2 /Ti

cantilevers leads to upward bending. Reproduced from Fang, W. & C.-Y. Lo (2000), by permission of Elsevier