Page 137 - Sami Franssila Introduction to Microfabrication

P. 137

116 Introduction to Microfabrication

Wet

etching

Plasma

etching

Electro-

plating

Ion implantation Lift-off

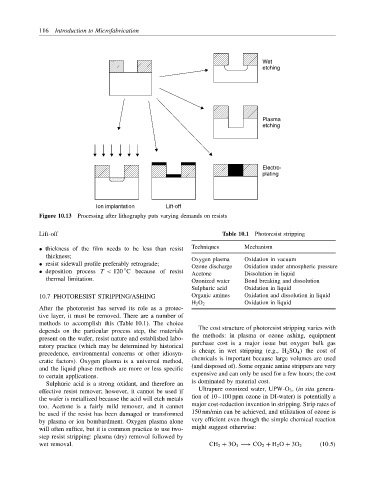

Figure 10.13 Processing after lithography puts varying demands on resists

Lift-off Table 10.1 Photoresist stripping

• thickness of the film needs to be less than resist Techniques Mechanism

thickness; Oxygen plasma Oxidation in vacuum

• resist sidewall profile preferably retrograde; Ozone discharge Oxidation under atmospheric pressure

◦

• deposition process T < 120 C because of resist

Acetone Dissolution in liquid

thermal limitation. Ozonized water Bond breaking and dissolution

Sulphuric acid Oxidation in liquid

10.7 PHOTORESIST STRIPPING/ASHING Organic amines Oxidation and dissolution in liquid

H 2 O 2 Oxidation in liquid

After the photoresist has served its role as a protec-

tive layer, it must be removed. There are a number of

methods to accomplish this (Table 10.1). The choice

depends on the particular process step, the materials The cost structure of photoresist stripping varies with

present on the wafer, resist nature and established labo- the methods: in plasma or ozone ashing, equipment

ratory practice (which may be determined by historical purchase cost is a major issue but oxygen bulk gas

precedence, environmental concerns or other idiosyn- is cheap; in wet stripping (e.g., H 2 SO 4 ) the cost of

cratic factors). Oxygen plasma is a universal method, chemicals is important because large volumes are used

and the liquid phase methods are more or less specific (and disposed of). Some organic amine strippers are very

to certain applications. expensive and can only be used for a few hours; the cost

Sulphuric acid is a strong oxidant, and therefore an is dominated by material cost.

effective resist remover; however, it cannot be used if Ultrapure ozonized water, UPW-O 3 , (in situ genera-

the wafer is metallized because the acid will etch metals tion of 10–100 ppm ozone in DI-water) is potentially a

major cost-reduction invention in stripping. Strip rates of

too. Acetone is a fairly mild remover, and it cannot

be used if the resist has been damaged or transformed 150 nm/min can be achieved, and utilization of ozone is

by plasma or ion bombardment. Oxygen plasma alone very efficient even though the simple chemical reaction

will often suffice, but it is common practice to use two- might suggest otherwise:

step resist stripping: plasma (dry) removal followed by

wet removal. CH 2 + 3O 3 −→ CO 2 + H 2 O + 3O 2 (10.5)