Page 133 - Sami Franssila Introduction to Microfabrication

P. 133

112 Introduction to Microfabrication

Thick polymer

Substrate Substrate

(a)

Substrate Substrate

Substrate Substrate

(a) (b)

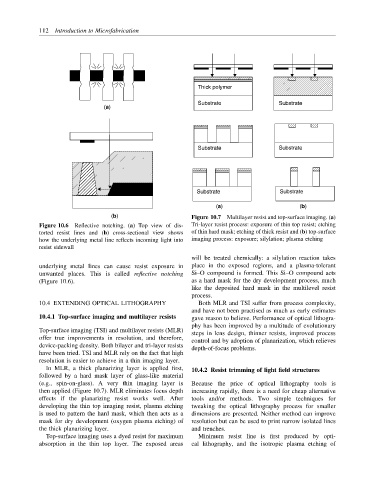

(b) Figure 10.7 Multilayer resist and top-surface imaging. (a)

Figure 10.6 Reflective notching. (a) Top view of dis- Tri-layer resist process: exposure of thin top resist; etching

torted resist lines and (b) cross-sectional view shows of thin hard mask; etching of thick resist and (b) top-surface

how the underlying metal line reflects incoming light into imaging process: exposure; silylation; plasma etching

resist sidewall

will be treated chemically: a silylation reaction takes

underlying metal lines can cause resist exposure in place in the exposed regions, and a plasma-tolerant

unwanted places. This is called reflective notching Si–O compound is formed. This Si–O compound acts

(Figure 10.6). as a hard mask for the dry development process, much

like the deposited hard mask in the multilevel resist

process.

10.4 EXTENDING OPTICAL LITHOGRAPHY Both MLR and TSI suffer from process complexity,

and have not been practised as much as early estimates

10.4.1 Top-surface imaging and multilayer resists gave reason to believe. Performance of optical lithogra-

phy has been improved by a multitude of evolutionary

Top-surface imaging (TSI) and multilayer resists (MLR) steps in lens design, thinner resists, improved process

offer true improvements in resolution, and therefore, control and by adoption of planarization, which relieves

device-packing density. Both bilayer and tri-layer resists depth-of-focus problems.

have been tried. TSI and MLR rely on the fact that high

resolution is easier to achieve in a thin imaging layer.

In MLR, a thick planarizing layer is applied first, 10.4.2 Resist trimming of light field structures

followed by a hard mask layer of glass-like material

(e.g., spin-on-glass). A very thin imaging layer is Because the price of optical lithography tools is

then applied (Figure 10.7). MLR eliminates focus depth increasing rapidly, there is a need for cheap alternative

effects if the planarizing resist works well. After tools and/or methods. Two simple techniques for

developing the thin top imaging resist, plasma etching tweaking the optical lithography process for smaller

is used to pattern the hard mask, which then acts as a dimensions are presented. Neither method can improve

mask for dry development (oxygen plasma etching) of resolution but can be used to print narrow isolated lines

the thick planarizing layer. and trenches.

Top-surface imaging uses a dyed resist for maximum Minimum resist line is first produced by opti-

absorption in the thin top layer. The exposed areas cal lithography, and the isotropic plasma etching of