Page 131 - Sami Franssila Introduction to Microfabrication

P. 131

110 Introduction to Microfabrication

d 0 d o

Thickness remaining d c Thickness remaining d i

1 10 100 1 10 100

2

2

Dose (mJ/cm ) Dose (mJ/cm )

(a) (b)

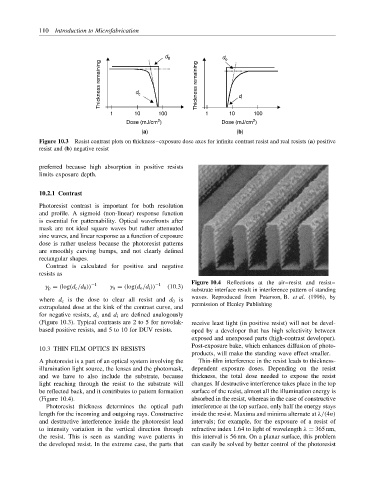

Figure 10.3 Resist contrast plots on thickness–exposure dose axes for infinite contrast resist and real resists (a) positive

resist and (b) negative resist

preferred because high absorption in positive resists

limits exposure depth.

10.2.1 Contrast

Photoresist contrast is important for both resolution

and profile. A sigmoid (non-linear) response function

is essential for patternability. Optical wavefronts after

mask are not ideal square waves but rather attenuated

sine waves, and linear response as a function of exposure

dose is rather useless because the photoresist patterns

are smoothly curving bumps, and not clearly defined

rectangular shapes.

Contrast is calculated for positive and negative

resists as

Figure 10.4 Reflections at the air–resist and resist–

−1

−1

γ p = (log(d c /d 0 )) γ n = (log(d o /d i )) (10.3)

substrate interface result in interference pattern of standing

waves. Reproduced from Peterson, B. et al. (1996), by

where d c is the dose to clear all resist and d 0 is

permission of Henley Publishing

extrapolated dose at the kink of the contrast curve, and

for negative resists, d o and d i are defined analogously

(Figure 10.3). Typical contrasts are 2 to 5 for novolak- receive least light (in positive resist) will not be devel-

based positive resists, and 5 to 10 for DUV resists. oped by a developer that has high selectivity between

exposed and unexposed parts (high-contrast developer).

Post-exposure bake, which enhances diffusion of photo-

10.3 THIN FILM OPTICS IN RESISTS

products, will make the standing wave effect smaller.

A photoresist is a part of an optical system involving the Thin-film interference in the resist leads to thickness-

illumination light source, the lenses and the photomask, dependent exposure doses. Depending on the resist

and we have to also include the substrate, because thickness, the total dose needed to expose the resist

light reaching through the resist to the substrate will changes. If destructive interference takes place in the top

be reflected back, and it contributes to pattern formation surface of the resist, almost all the illumination energy is

(Figure 10.4). absorbed in the resist, whereas in the case of constructive

Photoresist thickness determines the optical path interference at the top surface, only half the energy stays

length for the incoming and outgoing rays. Constructive inside the resist. Maxima and minima alternate at λ/(4n)

and destructive interference inside the photoresist lead intervals; for example, for the exposure of a resist of

to intensity variation in the vertical direction through refractive index 1.64 to light of wavelength λ = 365 nm,

the resist. This is seen as standing wave patterns in this interval is 56 nm. On a planar surface, this problem

the developed resist. In the extreme case, the parts that can easily be solved by better control of the photoresist