Page 130 - Sami Franssila Introduction to Microfabrication

P. 130

Lithographic Patterns 109

O

C O COOH

N 2

UV H 2 O

+ N 2

SO 2 SO 2 SO 2

R R R

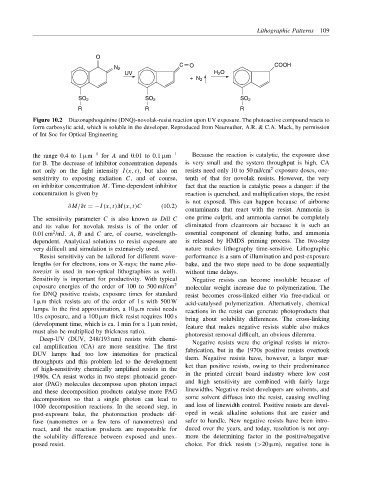

Figure 10.2 Diazonapthoquinine (DNQ)-novolak-resist reaction upon UV exposure. The photoactive compound reacts to

form carboxylic acid, which is soluble in the developer. Reproduced from Neureuther, A.R. & C.A. Mack, by permission

of Int Soc for Optical Engineering

the range 0.4 to 1 µm −1 for A and 0.01 to 0.1 µm −1 Because the reaction is catalytic, the exposure dose

for B. The decrease of inhibitor concentration depends is very small and the system throughput is high. CA

2

not only on the light intensity I (x, t), but also on resists need only 10 to 50 mJ/cm exposure doses, one-

sensitivity to exposing radiation C, and of course, tenth of that for novolak resists. However, the very

on inhibitor concentration M. Time-dependent inhibitor fact that the reaction is catalytic poses a danger: if the

concentration is given by reaction is quenched, and multiplication stops, the resist

is not exposed. This can happen because of airborne

∂M/∂t = −I (x, t)M(x, t)C (10.2)

contaminants that react with the resist. Ammonia is

The sensitivity parameter C is also known as Dill C one prime culprit, and ammonia cannot be completely

and its value for novolak resists is of the order of eliminated from cleanroom air because it is such an

2

0.01 cm /mJ. A, B and C are, of course, wavelength- essential component of cleaning baths, and ammonia

dependent. Analytical solutions to resist exposure are is released by HMDS priming process. The two-step

very difficult and simulation is extensively used. nature makes lithography time-sensitive. Lithographic

Resist sensitivity can be tailored for different wave- performance is a sum of illumination and post-exposure

lengths (or for electrons, ions or X-rays; the name pho- bake, and the two steps need to be done sequentially

toresist is used in non-optical lithographies as well). without time delays.

Sensitivity is important for productivity. With typical Negative resists can become insoluble because of

exposure energies of the order of 100 to 500 mJ/cm 2 molecular weight increase due to polymerization. The

for DNQ positive resists, exposure times for standard resist becomes cross-linked either via free-radical or

1 µm thick resists are of the order of 1 s with 500 W acid-catalysed polymerization. Alternatively, chemical

lamps. In the first approximation, a 10 µm resist needs reactions in the resist can generate photoproducts that

10 s exposure, and a 100 µm thick resist requires 100 s bring about solubility differences. The cross-linking

(development time, which is ca. 1 min for a 1 µm resist, feature that makes negative resists stable also makes

must also be multiplied by thickness ratio). photoresist removal difficult, an obvious dilemma.

Deep-UV (DUV, 248/193 nm) resists with chemi-

cal amplification (CA) are more sensitive. The first Negative resists were the original resists in micro-

fabrication, but in the 1970s positive resists overtook

DUV lamps had too low intensities for practical

them. Negative resists have, however, a larger mar-

throughputs and this problem led to the development

of high-sensitivity chemically amplified resists in the ket than positive resists, owing to their predominance

1980s. CA resist works in two steps: photoacid gener- in the printed circuit board industry where low cost

ator (PAG) molecules decompose upon photon impact and high sensitivity are combined with fairly large

and these decomposition products catalyse more PAG linewidths. Negative resist developers are solvents, and

decomposition so that a single photon can lead to some solvent diffuses into the resist, causing swelling

1000 decomposition reactions. In the second step, in and loss of linewidth control. Positive resists are devel-

post-exposure bake, the photoreaction products dif- oped in weak alkaline solutions that are easier and

fuse (nanometres or a few tens of nanometres) and safer to handle. New negative resists have been intro-

react, and the reaction products are responsible for duced over the years, and today, resolution is not any-

the solubility difference between exposed and unex- more the determining factor in the positive/negative

posed resist. choice. For thick resists (>20 µm), negative tone is