Page 151 - Sami Franssila Introduction to Microfabrication

P. 151

130 Introduction to Microfabrication

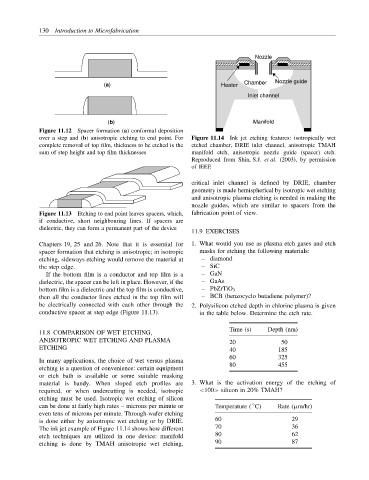

Nozzle

(a) Heater Chamber Nozzle guide

Inlet channel

(b) Manifold

Figure 11.12 Spacer formation (a) conformal deposition

over a step and (b) anisotropic etching to end point. For Figure 11.14 Ink jet etching features: isotropically wet

complete removal of top film, thickness to be etched is the etched chamber, DRIE inlet channel, anisotropic TMAH

sum of step height and top film thicknesses manifold etch, anisotropic nozzle guide (spacer) etch.

Reproduced from Shin, S.J. et al. (2003), by permission

of IEEE

critical inlet channel is defined by DRIE, chamber

geometry is made hemispherical by isotropic wet etching

and anisotropic plasma etching is needed in making the

nozzle guides, which are similar to spacers from the

Figure 11.13 Etching to end point leaves spacers, which, fabrication point of view.

if conductive, short neighbouring lines. If spacers are

dielectric, they can form a permanent part of the device

11.9 EXERCISES

Chapters 19, 25 and 26. Note that it is essential for 1. What would you use as plasma etch gases and etch

spacer formation that etching is anisotropic; in isotropic masks for etching the following materials:

etching, sideways etching would remove the material at – diamond

the step edge. – SiC

If the bottom film is a conductor and top film is a – GaN

dielectric, the spacer can be left in place. However, if the – GaAs

bottom film is a dielectric and the top film is conductive, – PbZrTiO 3

then all the conductor lines etched in the top film will – BCB (benzocyclo butadiene polymer)?

be electrically connected with each other through the 2. Polysilicon etched depth in chlorine plasma is given

conductive spacer at step edge (Figure 11.13). in the table below. Determine the etch rate.

Time (s) Depth (nm)

11.8 COMPARISON OF WET ETCHING,

ANISOTROPIC WET ETCHING AND PLASMA 20 50

ETCHING 40 185

60 325

In many applications, the choice of wet versus plasma

etching is a question of convenience: certain equipment 80 455

or etch bath is available or some suitable masking

material is handy. When sloped etch profiles are 3. What is the activation energy of the etching of

required, or when undercutting is needed, isotropic <100> silicon in 20% TMAH?

etching must be used. Isotropic wet etching of silicon

◦

can be done at fairly high rates – microns per minute or Temperature ( C) Rate (µm/hr)

even tens of microns per minute. Through-wafer etching

is done either by anisotropic wet etching or by DRIE. 60 29

The ink jet example of Figure 11.14 shows how different 70 36

etch techniques are utilized in one device: manifold 80 62

etching is done by TMAH anisotropic wet etching, 90 87