Page 209 - Sami Franssila Introduction to Microfabrication

P. 209

188 Introduction to Microfabrication

Press Force frame

Heater

Stamp master

Wafer

Heater

(a) (b)

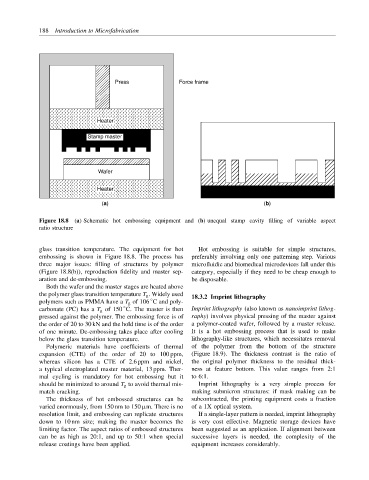

Figure 18.8 (a) Schematic hot embossing equipment and (b) unequal stamp cavity filling of variable aspect

ratio structure

glass transition temperature. The equipment for hot Hot embossing is suitable for simple structures,

embossing is shown in Figure 18.8. The process has preferably involving only one patterning step. Various

three major issues: filling of structures by polymer microfluidic and biomedical microdevices fall under this

(Figure 18.8(b)), reproduction fidelity and master sep- category, especially if they need to be cheap enough to

aration and de-embossing. be disposable.

Both the wafer and the master stages are heated above

the polymer glass transition temperature T g . Widely used 18.3.2 Imprint lithography

◦

polymers such as PMMA have a T g of 106 C and poly-

◦

carbonate (PC) has a T g of 150 C. The master is then Imprint lithography (also known as nanoimprint lithog-

pressed against the polymer. The embossing force is of raphy) involves physical pressing of the master against

the order of 20 to 30 kN and the hold time is of the order a polymer-coated wafer, followed by a master release.

of one minute. De-embossing takes place after cooling It is a hot embossing process that is used to make

below the glass transition temperature. lithography-like structures, which necessitates removal

Polymeric materials have coefficients of thermal of the polymer from the bottom of the structure

expansion (CTE) of the order of 20 to 100 ppm, (Figure 18.9). The thickness contrast is the ratio of

whereas silicon has a CTE of 2.6 ppm and nickel, the original polymer thickness to the residual thick-

a typical electroplated master material, 13 ppm. Ther- ness at feature bottom. This value ranges from 2:1

mal cycling is mandatory for hot embossing but it to 6:1.

should be minimized to around T g to avoid thermal mis- Imprint lithography is a very simple process for

match cracking. making submicron structures: if mask making can be

The thickness of hot embossed structures can be subcontracted, the printing equipment costs a fraction

varied enormously, from 150 nm to 150 µm. There is no of a 1X optical system.

resolution limit, and embossing can replicate structures If a single-layer pattern is needed, imprint lithography

down to 10 nm size; making the master becomes the is very cost effective. Magnetic storage devices have

limiting factor. The aspect ratios of embossed structures been suggested as an application. If alignment between

can be as high as 20:1, and up to 50:1 when special successive layers is needed, the complexity of the

release coatings have been applied. equipment increases considerably.