Page 205 - Sami Franssila Introduction to Microfabrication

P. 205

184 Introduction to Microfabrication

(a) (b)

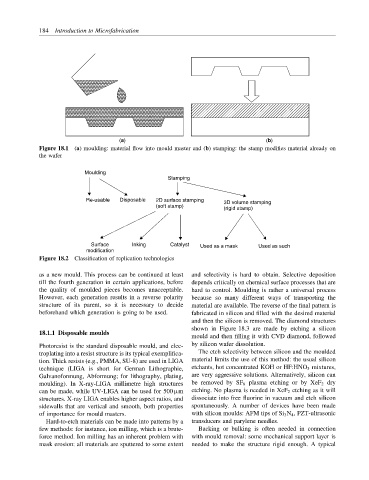

Figure 18.1 (a) moulding: material flow into mould master and (b) stamping: the stamp modifies material already on

the wafer

Moulding

Stamping

Re-usable Disposable 2D surface stamping 3D volume stamping

(soft stamp)

(rigid stamp)

Surface Inking Catalyst Used as a mask Used as such

modification

Figure 18.2 Classification of replication technologies

as a new mould. This process can be continued at least and selectivity is hard to obtain. Selective deposition

till the fourth generation in certain applications, before depends critically on chemical surface processes that are

the quality of moulded pieces becomes unacceptable. hard to control. Moulding is rather a universal process

However, each generation results in a reverse polarity because so many different ways of transporting the

structure of its parent, so it is necessary to decide material are available. The reverse of the final pattern is

beforehand which generation is going to be used. fabricated in silicon and filled with the desired material

and then the silicon is removed. The diamond structures

shown in Figure 18.3 are made by etching a silicon

18.1.1 Disposable moulds

mould and then filling it with CVD diamond, followed

Photoresist is the standard disposable mould, and elec- by silicon wafer dissolution.

troplating into a resist structure is its typical exemplifica- The etch selectivity between silicon and the moulded

tion. Thick resists (e.g., PMMA, SU-8) are used in LIGA material limits the use of this method: the usual silicon

technique (LIGA is short for German Lithographie, etchants, hot concentrated KOH or HF:HNO 3 mixtures,

Galvanoformung, Abformung; for lithography, plating, are very aggressive solutions. Alternatively, silicon can

moulding). In X-ray-LIGA millimetre high structures be removed by SF 6 plasma etching or by XeF 2 dry

can be made, while UV-LIGA can be used for 500 µm etching. No plasma is needed in XeF 2 etching as it will

structures. X-ray LIGA enables higher aspect ratios, and dissociate into free fluorine in vacuum and etch silicon

sidewalls that are vertical and smooth, both properties spontaneously. A number of devices have been made

of importance for mould masters. with silicon moulds: AFM tips of Si 3 N 4 , PZT-ultrasonic

Hard-to-etch materials can be made into patterns by a transducers and parylene needles.

few methods: for instance, ion milling, which is a brute- Backing or bulking is often needed in connection

force method. Ion milling has an inherent problem with with mould removal: some mechanical support layer is

mask erosion: all materials are sputtered to some extent needed to make the structure rigid enough. A typical