Page 398 - Sami Franssila Introduction to Microfabrication

P. 398

Microfabrication at Large 377

Via bridge Via plug

Device

surface

Third level

(thinned

substrate)

Bond

(face-to-back)

Device

Second level surface

(thinned

substrate)

Bond

(face-to-face)

First level

Device

surface

Figure 39.3 Chip stacking by wafer thinning and adhesive bonding. Reproduced from Lu, J.-Q. et al. (2000), by

permission of Materials Research Society

N 2 Locally bonded area N + H 2 In all cases, CMOS provides individually addressable

2

pixels. Fingerprint detectors with pressure-sensitive

Glass microstructures have been demonstrated for a variety

of applications.

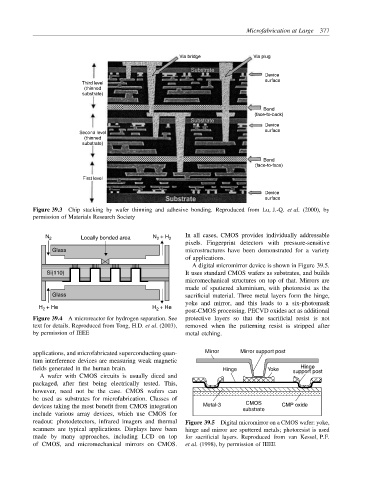

A digital micromirror device is shown in Figure 39.5.

Si(110) It uses standard CMOS wafers as substrates, and builds

micromechanical structures on top of that. Mirrors are

made of sputtered aluminium, with photoresist as the

Glass sacrificial material. Three metal layers form the hinge,

yoke and mirror, and this leads to a six-photomask

H + He H + He

2

2

post-CMOS processing. PECVD oxides act as additional

Figure 39.4 A microreactor for hydrogen separation. See protective layers so that the sacrificial resist is not

text for details. Reproduced from Tong, H.D. et al. (2003), removed when the patterning resist is stripped after

by permission of IEEE metal etching.

applications, and microfabricated superconducting quan- Mirror Mirror support post

tum interference devices are measuring weak magnetic

Hinge

fields generated in the human brain. Hinge Yoke support post

A wafer with CMOS circuits is usually diced and

packaged, after first being electrically tested. This,

however, need not be the case. CMOS wafers can

be used as substrates for microfabrication. Classes of

CMOS

devices taking the most benefit from CMOS integration Metal-3 substrate CMP oxide

include various array devices, which use CMOS for

readout: photodetectors, infrared imagers and thermal Figure 39.5 Digital micromirror on a CMOS wafer: yoke,

scanners are typical applications. Displays have been hinge and mirror are sputtered metals; photoresist is used

made by many approaches, including LCD on top for sacrificial layers. Reproduced from van Kessel, P.F.

of CMOS, and micromechanical mirrors on CMOS. et al. (1998), by permission of IEEE