Page 227 - Lean six sigma demystified

P. 227

Chapter 5 Redu C ing d efe C t S with Six Sigm a 205

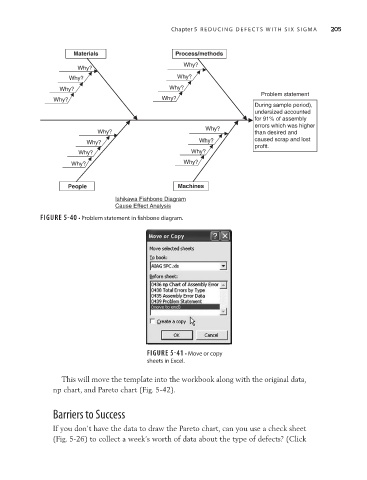

Materials Process/methods

Why?

Why?

Why? Why?

Why? Why?

Problem statement

Why? Why?

During sample period),

undersized accounted

for 91% of assembly

errors which was higher

Why?

Why? than desired and

Why? Why? caused scrap and lost

profit.

Why? Why?

Why? Why?

People Machines

Ishikawa Fishbone Diagram

Cause Effect Analysis

FIGURE 5-40 • Problem statement in fishbone diagram.

FIGURE 5-41 • Move or copy

sheets in Excel.

This will move the template into the workbook along with the original data,

np chart, and Pareto chart (Fig. 5-42).

Barriers to Success

If you don’t have the data to draw the Pareto chart, can you use a check sheet

(Fig. 5-26) to collect a week’s worth of data about the type of defects? (Click