Page 277 - Low Temperature Energy Systems with Applications of Renewable Energy

P. 277

Biofuels conversion: energy-saving processes and use of biogas 263

Fig. 7.3 Gas development route to 2050 for the Netherlands, modified from [4].

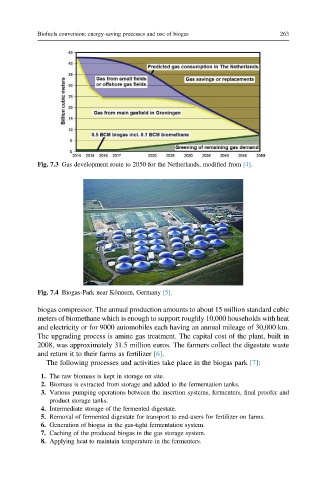

Fig. 7.4 Biogas-Park near K€ onnern, Germany [5].

biogas compressor. The annual production amounts to about 15 million standard cubic

meters of biomethane which is enough to support roughly 10,000 households with heat

and electricity or for 9000 automobiles each having an annual mileage of 30,000 km.

The upgrading process is amine gas treatment. The capital cost of the plant, built in

2008, was approximately 31.5 million euros. The farmers collect the digestate waste

and return it to their farms as fertilizer [6].

The following processes and activities take place in the biogas park [7]:

1. The raw biomass is kept in storage on site.

2. Biomass is extracted from storage and added to the fermentation tanks.

3. Various pumping operations between the insertion systems, fermenters, final proofer and

product storage tanks.

4. Intermediate storage of the fermented digestate.

5. Removal of fermented digestate for transport to end-users for fertilizer on farms.

6. Generation of biogas in the gas-tight fermentation system.

7. Caching of the produced biogas in the gas storage system.

8. Applying heat to maintain temperature in the fermenters.