Page 280 - Low Temperature Energy Systems with Applications of Renewable Energy

P. 280

266 Low-Temperature Energy Systems with Applications of Renewable Energy

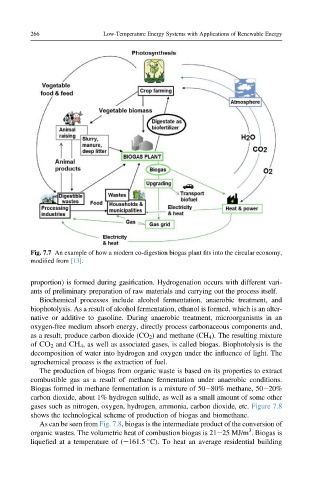

Fig. 7.7 An example of how a modern co-digestion biogas plant fits into the circular economy,

modified from [13].

proportion) is formed during gasification. Hydrogenation occurs with different vari-

ants of preliminary preparation of raw materials and carrying out the process itself.

Biochemical processes include alcohol fermentation, anaerobic treatment, and

biophotolysis. As a result of alcohol fermentation, ethanol is formed, which is an alter-

native or additive to gasoline. During anaerobic treatment, microorganisms in an

oxygen-free medium absorb energy, directly process carbonaceous components and,

as a result, produce carbon dioxide (CO 2 ) and methane (CH 4 ). The resulting mixture

of SP 2 and SO 4 , as well as associated gases, is called biogas. Biophotolysis is the

decomposition of water into hydrogen and oxygen under the influence of light. The

agrochemical process is the extraction of fuel.

The production of biogas from organic waste is based on its properties to extract

combustible gas as a result of methane fermentation under anaerobic conditions.

Biogas formed in methane fermentation is a mixture of 50e80% methane, 50e20%

carbon dioxide, about 1% hydrogen sulfide, as well as a small amount of some other

gases such as nitrogen, oxygen, hydrogen, ammonia, carbon dioxide, etc. Figure 7.8

shows the technological scheme of production of biogas and biomethane.

As can be seen from Fig. 7.8, biogas is the intermediate product of the conversion of

3

organic wastes. The volumetric heat of combustion biogas is 21e25 MJ/m . Biogas is

liquefied at a temperature of (e161.5 C). To heat an average residential building