Page 169 - MEMS Mechanical Sensors

P. 169

158 Force and Torque Sensors

Comb drive

Anchor actuators

i sense

V drive

F tf

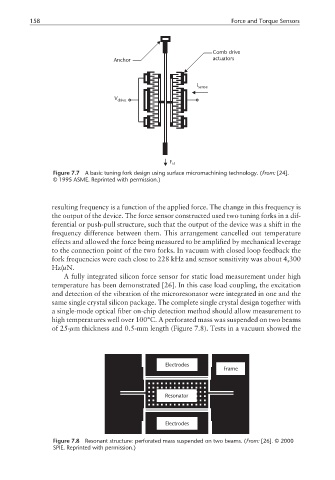

Figure 7.7 A basic tuning fork design using surface micromachining technology. (From: [24].

© 1995 ASME. Reprinted with permission.)

resulting frequency is a function of the applied force. The change in this frequency is

the output of the device. The force sensor constructed used two tuning forks in a dif-

ferential or push-pull structure, such that the output of the device was a shift in the

frequency difference between them. This arrangement cancelled out temperature

effects and allowed the force being measured to be amplified by mechanical leverage

to the connection point of the two forks. In vacuum with closed loop feedback the

fork frequencies were each close to 228 kHz and sensor sensitivity was about 4,300

Hz/µN.

A fully integrated silicon force sensor for static load measurement under high

temperature has been demonstrated [26]. In this case load coupling, the excitation

and detection of the vibration of the microresonator were integrated in one and the

same single crystal silicon package. The complete single crystal design together with

a single-mode optical fiber on-chip detection method should allow measurement to

high temperatures well over 100°C. A perforated mass was suspended on two beams

of 25-µm thickness and 0.5-mm length (Figure 7.8). Tests in a vacuum showed the

Electrodes

Frame

Resonator

Electrodes

Figure 7.8 Resonant structure: perforated mass suspended on two beams. (From: [26]. © 2000

SPIE. Reprinted with permission.)