Page 172 - MEMS Mechanical Sensors

P. 172

7.5 Capacitive Devices 161

and electromagnetic interference can be a problem [49, 50]. Torque can be meas-

ured by the use of a set of electrodes on one end of a torsion bar connected to a shaft

and a second set of electrodes on the outside of a thin tube of dielectric material

[51]. This tube is fixed to the shaft at the other end of the torsion bar. One set of

electrodes moves with respect to the second set when torque is applied such that

there is capacitance variation between the two sets of electrodes. The capacitance is

part of a resonance circuit inductively linked to a coil on the stationary part. Each

end of a torsion bar can have a noncontact capacitive angular displacement sensor,

and the torque twist is monitored by electrical phase change.

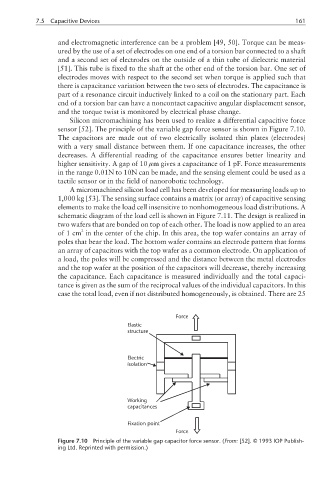

Silicon micromachining has been used to realize a differential capacitive force

sensor [52]. The principle of the variable gap force sensor is shown in Figure 7.10.

The capacitors are made out of two electrically isolated thin plates (electrodes)

with a very small distance between them. If one capacitance increases, the other

decreases. A differential reading of the capacitance ensures better linearity and

higher sensitivity. A gap of 10 µm gives a capacitance of 1 pF. Force measurements

in the range 0.01N to 10N can be made, and the sensing element could be used as a

tactile sensor or in the field of nanorobotic technology.

A micromachined silicon load cell has been developed for measuring loads up to

1,000 kg [53]. The sensing surface contains a matrix (or array) of capacitive sensing

elements to make the load cell insensitive to nonhomogeneous load distributions. A

schematic diagram of the load cell is shown in Figure 7.11. The design is realized in

two wafers that are bonded on top of each other. The load is now applied to an area

2

of1cm in the center of the chip. In this area, the top wafer contains an array of

poles that bear the load. The bottom wafer contains an electrode pattern that forms

an array of capacitors with the top wafer as a common electrode. On application of

a load, the poles will be compressed and the distance between the metal electrodes

and the top wafer at the position of the capacitors will decrease, thereby increasing

the capacitance. Each capacitance is measured individually and the total capaci-

tance is given as the sum of the reciprocal values of the individual capacitors. In this

case the total load, even if not distributed homogeneously, is obtained. There are 25

Force

Elastic

structure

Electric

isolation

Working

capacitances

Fixation point

Force

Figure 7.10 Principle of the variable gap capacitor force sensor. (From: [52]. © 1993 IOP Publish-

ing Ltd. Reprinted with permission.)