Page 198 - MEMS Mechanical Sensors

P. 198

8.2 Micromachined Accelerometer 187

PZT element

Top Supporting

electrode

beam

Inertial mass

(a) (b)

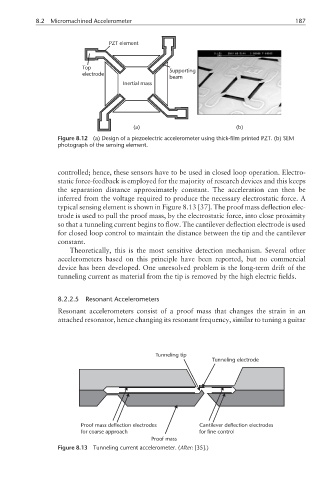

Figure 8.12 (a) Design of a piezoelectric accelerometer using thick-film printed PZT. (b) SEM

photograph of the sensing element.

controlled; hence, these sensors have to be used in closed loop operation. Electro-

static force-feedback is employed for the majority of research devices and this keeps

the separation distance approximately constant. The acceleration can then be

inferred from the voltage required to produce the necessary electrostatic force. A

typical sensing element is shown in Figure 8.13 [37]. The proof mass deflection elec-

trode is used to pull the proof mass, by the electrostatic force, into close proximity

so that a tunneling current begins to flow. The cantilever deflection electrode is used

for closed loop control to maintain the distance between the tip and the cantilever

constant.

Theoretically, this is the most sensitive detection mechanism. Several other

accelerometers based on this principle have been reported, but no commercial

device has been developed. One unresolved problem is the long-term drift of the

tunneling current as material from the tip is removed by the high electric fields.

8.2.2.5 Resonant Accelerometers

Resonant accelerometers consist of a proof mass that changes the strain in an

attached resonator, hence changing its resonant frequency, similar to tuning a guitar

Tunneling tip

Tunneling electrode

Proof mass deflection electrodes Cantilever deflection electrodes

for coarse approach for fine control

Proof mass

Figure 8.13 Tunneling current accelerometer. (After: [35].)