Page 194 - MEMS Mechanical Sensors

P. 194

8.2 Micromachined Accelerometer 183

Top electrode

Seismic mass

} } } C 1

Bottom

x

electrode

} } } C 2 1mm

5mm

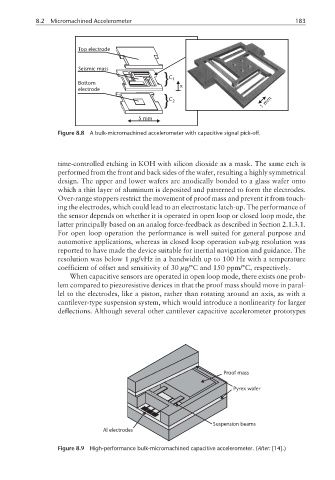

Figure 8.8 A bulk-micromachined accelerometer with capacitive signal pick-off.

time-controlled etching in KOH with silicon dioxide as a mask. The same etch is

performed from the front and back sides of the wafer, resulting a highly symmetrical

design. The upper and lower wafers are anodically bonded to a glass wafer onto

which a thin layer of aluminum is deposited and patterned to form the electrodes.

Over-range stoppers restrict the movement of proof mass and prevent it from touch-

ing the electrodes, which could lead to an electrostatic latch-up. The performance of

the sensor depends on whether it is operated in open loop or closed loop mode, the

latter principally based on an analog force-feedback as described in Section 2.1.3.1.

For open loop operation the performance is well suited for general purpose and

automotive applications, whereas in closed loop operation sub-µg resolution was

reported to have made the device suitable for inertial navigation and guidance. The

resolution was below 1 µg/vHz in a bandwidth up to 100 Hz with a temperature

coefficient of offset and sensitivity of 30 µg/°C and 150 ppm/°C, respectively.

When capacitive sensors are operated in open loop mode, there exists one prob-

lem compared to piezoresistive devices in that the proof mass should move in paral-

lel to the electrodes, like a piston, rather than rotating around an axis, as with a

cantilever-type suspension system, which would introduce a nonlinearity for larger

deflections. Although several other cantilever capacitive accelerometer prototypes

Proof mass

Pyrex wafer

Suspension beams

Al electrodes

Figure 8.9 High-performance bulk-micromachined capacitive accelerometer. (After: [14].)