Page 197 - MEMS Mechanical Sensors

P. 197

186 Inertial Sensors

Metal contacts

Damping holes

Silicon

proof mass

Polysilicon

top/bottom Polysilicon

electrode stiffeners Proof mass

suspension beams

Cross-sectional

view

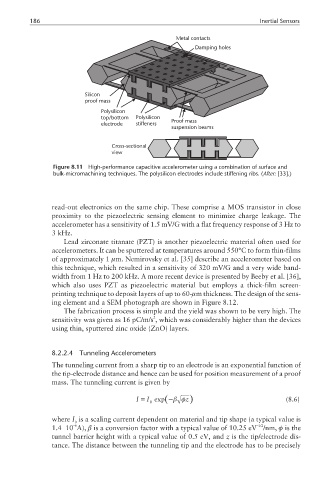

Figure 8.11 High-performance capacitive accelerometer using a combination of surface and

bulk-micromachining techniques. The polysilicon electrodes include stiffening ribs. (After: [33].)

read-out electronics on the same chip. These comprise a MOS transistor in close

proximity to the piezoelectric sensing element to minimize charge leakage. The

accelerometer has a sensitivity of 1.5 mV/G with a flat frequency response of 3 Hz to

3 kHz.

Lead zirconate titanate (PZT) is another piezoelectric material often used for

accelerometers. It can be sputtered at temperatures around 550°C to form thin-films

of approximately 1 µm. Nemirovsky et al. [35] describe an accelerometer based on

this technique, which resulted in a sensitivity of 320 mV/G and a very wide band-

width from 1 Hz to 200 kHz. A more recent device is presented by Beeby et al. [36],

which also uses PZT as piezoelectric material but employs a thick-film screen-

printing technique to deposit layers of up to 60-µm thickness. The design of the sens-

ing element and a SEM photograph are shown in Figure 8.12.

The fabrication process is simple and the yield was shown to be very high. The

2

sensitivity was given as 16 pC/m/s , which was considerably higher than the devices

using thin, sputtered zinc oxide (ZnO) layers.

8.2.2.4 Tunneling Accelerometers

The tunneling current from a sharp tip to an electrode is an exponential function of

the tip-electrode distance and hence can be used for position measurement of a proof

mass. The tunneling current is given by

I = I exp (−βφ z ) (8.6)

0

where I is a scaling current dependent on material and tip shape (a typical value is

0

–1/2

–6

1.4 10 A), β is a conversion factor with a typical value of 10.25 eV /nm, φ is the

tunnel barrier height with a typical value of 0.5 eV, and z is the tip/electrode dis-

tance. The distance between the tunneling tip and the electrode has to be precisely