Page 260 - MEMS Mechanical Sensors

P. 260

9.11 Conclusion 249

Out-of-plane bent

silicon beam structure Bond pads

Hot-wires

Polysilicon

hot-wire

Cured

polyimide

Metal

Silicon beam

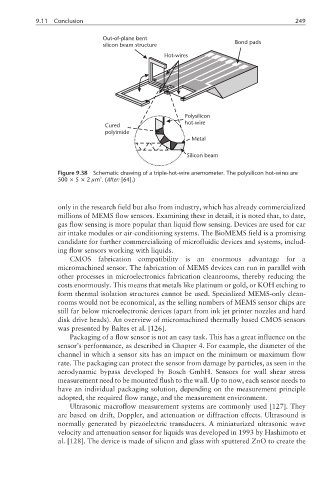

Figure 9.38 Schematic drawing of a triple-hot-wire anemometer. The polysilicon hot-wires are

3

500 × 5 × 2 µm .(After: [64].)

only in the research field but also from industry, which has already commercialized

millions of MEMS flow sensors. Examining these in detail, it is noted that, to date,

gas flow sensing is more popular than liquid flow sensing. Devices are used for car

air intake modules or air-conditioning systems. The BioMEMS field is a promising

candidate for further commercializing of microfluidic devices and systems, includ-

ing flow sensors working with liquids.

CMOS fabrication compatibility is an enormous advantage for a

micromachined sensor. The fabrication of MEMS devices can run in parallel with

other processes in microelectronics fabrication cleanrooms, thereby reducing the

costs enormously. This means that metals like platinum or gold, or KOH etching to

form thermal isolation structures cannot be used. Specialized MEMS-only clean-

rooms would not be economical, as the selling numbers of MEMS sensor chips are

still far below microelectronic devices (apart from ink jet printer nozzles and hard

disk drive heads). An overview of micromachined thermally based CMOS sensors

was presented by Baltes et al. [126].

Packaging of a flow sensor is not an easy task. This has a great influence on the

sensor’s performance, as described in Chapter 4. For example, the diameter of the

channel in which a sensor sits has an impact on the minimum or maximum flow

rate. The packaging can protect the sensor from damage by particles, as seen in the

aerodynamic bypass developed by Bosch GmbH. Sensors for wall shear stress

measurement need to be mounted flush to the wall. Up to now, each sensor needs to

have an individual packaging solution, depending on the measurement principle

adopted, the required flow range, and the measurement environment.

Ultrasonic macroflow measurement systems are commonly used [127]. They

are based on drift, Doppler, and attenuation or diffraction effects. Ultrasound is

normally generated by piezoelectric transducers. A miniaturized ultrasonic wave

velocity and attenuation sensor for liquids was developed in 1993 by Hashimoto et

al. [128]. The device is made of silicon and glass with sputtered ZnO to create the