Page 81 - MEMS Mechanical Sensors

P. 81

70 Mechanical Sensor Packaging

liquid water forming at the interface [27]. These polymers, however, offer poor lev-

els of protection against alkaline solutions.

Protective silicon oxide and silicon nitride films possess a much greater resis-

tance to the diffusion of water molecules. These films can be applied both at wafer

level and on mounted chips using CVD processes. They must be free from cracks and

pinholes, and in the case of mounted chips, the films must be deposited on all the

exposed surfaces, including wirebonds and contact pads. The chemical resistance of

these films is fundamentally important since they will only be deposited in thick-

nesses of a few microns. Even very low corrosion rates (27 angstroms/day) will

remove a 1-micron-thick protective film after 1 year. Silicon carbide thin-films have

been found to offer the most promising levels of chemical resistance [28]. A further

consideration is the effects of thermal cycling, which can cause delamination of these

films due to TEC mismatches.

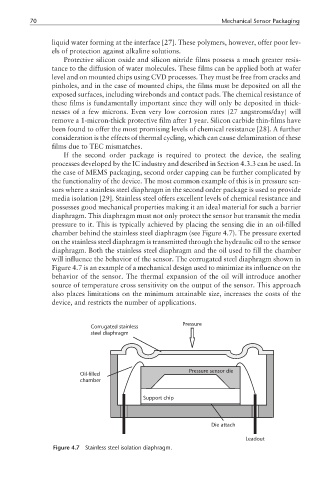

If the second order package is required to protect the device, the sealing

processes developed by the IC industry and described in Section 4.3.3 can be used. In

the case of MEMS packaging, second order capping can be further complicated by

the functionality of the device. The most common example of this is in pressure sen-

sors where a stainless steel diaphragm in the second order package is used to provide

media isolation [29]. Stainless steel offers excellent levels of chemical resistance and

possesses good mechanical properties making it an ideal material for such a barrier

diaphragm. This diaphragm must not only protect the sensor but transmit the media

pressure to it. This is typically achieved by placing the sensing die in an oil-filled

chamber behind the stainless steel diaphragm (see Figure 4.7). The pressure exerted

on the stainless steel diaphragm is transmitted through the hydraulic oil to the sensor

diaphragm. Both the stainless steel diaphragm and the oil used to fill the chamber

will influence the behavior of the sensor. The corrugated steel diaphragm shown in

Figure 4.7 is an example of a mechanical design used to minimize its influence on the

behavior of the sensor. The thermal expansion of the oil will introduce another

source of temperature cross sensitivity on the output of the sensor. This approach

also places limitations on the minimum attainable size, increases the costs of the

device, and restricts the number of applications.

Pressure

Corrugated stainless

steel diaphragm

Pressure sensor die

Oil-filled

chamber

Support chip

Die attach

Leadout

Figure 4.7 Stainless steel isolation diaphragm.