Page 86 - MEMS Mechanical Sensors

P. 86

4.4 MEMS Mechanical Sensor Packaging 75

TO header

Pressure sensor die

Corrugated Die attach

silicon

support chip Leadout

Pressure port

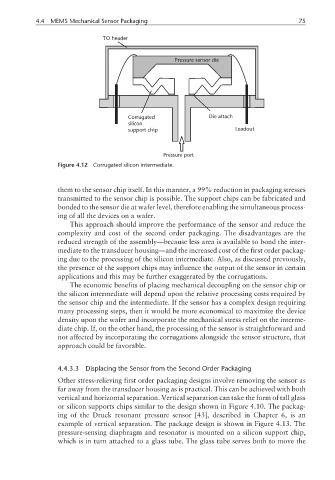

Figure 4.12 Corrugated silicon intermediate.

them to the sensor chip itself. In this manner, a 99% reduction in packaging stresses

transmitted to the sensor chip is possible. The support chips can be fabricated and

bonded to the sensor die at wafer level, therefore enabling the simultaneous process-

ing of all the devices on a wafer.

This approach should improve the performance of the sensor and reduce the

complexity and cost of the second order packaging. The disadvantages are the

reduced strength of the assembly—because less area is available to bond the inter-

mediate to the transducer housing—and the increased cost of the first order packag-

ing due to the processing of the silicon intermediate. Also, as discussed previously,

the presence of the support chips may influence the output of the sensor in certain

applications and this may be further exaggerated by the corrugations.

The economic benefits of placing mechanical decoupling on the sensor chip or

the silicon intermediate will depend upon the relative processing costs required by

the sensor chip and the intermediate. If the sensor has a complex design requiring

many processing steps, then it would be more economical to maximize the device

density upon the wafer and incorporate the mechanical stress relief on the interme-

diate chip. If, on the other hand, the processing of the sensor is straightforward and

not affected by incorporating the corrugations alongside the sensor structure, that

approach could be favorable.

4.4.3.3 Displacing the Sensor from the Second Order Packaging

Other stress-relieving first order packaging designs involve removing the sensor as

far away from the transducer housing as is practical. This can be achieved with both

vertical and horizontal separation. Vertical separation can take the form of tall glass

or silicon supports chips similar to the design shown in Figure 4.10. The packag-

ing of the Druck resonant pressure sensor [43], described in Chapter 6, is an

example of vertical separation. The package design is shown in Figure 4.13. The

pressure-sensing diaphragm and resonator is mounted on a silicon support chip,

which is in turn attached to a glass tube. The glass tube serves both to move the