Page 87 - MEMS Mechanical Sensors

P. 87

76 Mechanical Sensor Packaging

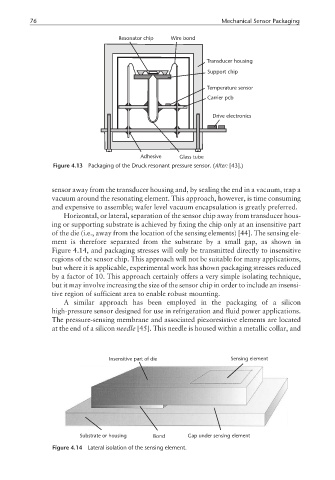

Resonator chip Wire bond

Transducer housing

Support chip

Temperature sensor

Carrier pcb

Drive electronics

Adhesive Glass tube

Figure 4.13 Packaging of the Druck resonant pressure sensor. (After: [43].)

sensor away from the transducer housing and, by sealing the end in a vacuum, trap a

vacuum around the resonating element. This approach, however, is time consuming

and expensive to assemble; wafer level vacuum encapsulation is greatly preferred.

Horizontal, or lateral, separation of the sensor chip away from transducer hous-

ing or supporting substrate is achieved by fixing the chip only at an insensitive part

of the die (i.e., away from the location of the sensing elements) [44]. The sensing ele-

ment is therefore separated from the substrate by a small gap, as shown in

Figure 4.14, and packaging stresses will only be transmitted directly to insensitive

regions of the sensor chip. This approach will not be suitable for many applications,

but where it is applicable, experimental work has shown packaging stresses reduced

by a factor of 10. This approach certainly offers a very simple isolating technique,

but it may involve increasing the size of the sensor chip in order to include an insensi-

tive region of sufficient area to enable robust mounting.

A similar approach has been employed in the packaging of a silicon

high-pressure sensor designed for use in refrigeration and fluid power applications.

The pressure-sensing membrane and associated piezoresistive elements are located

at the end of a silicon needle [45]. This needle is housed within a metallic collar, and

Insensitive part of die Sensing element

Substrate or housing Bond Gap under sensing element

Figure 4.14 Lateral isolation of the sensing element.