Page 83 - MEMS Mechanical Sensors

P. 83

72 Mechanical Sensor Packaging

While this applies equally to capacitive, piezoresistive, and resonant devices, the per-

formance advantages offered by resonant sensing can only be achieved with capable

package design. One of the major undesirable influences is the effect of temperature

changes on the packaged sensor assembly. Uneven thermal expansion coefficients of

the different materials making up the packaged assembly often induce stresses across

the sensor chip. Similar packaging stresses can also be induced by the application of

mechanical forces onto the second order packaging, changes in humidity, the pres-

ence of vibrations, or be in-built in the assembly during the packaging process.

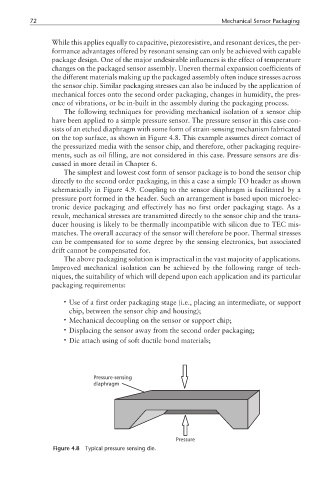

The following techniques for providing mechanical isolation of a sensor chip

have been applied to a simple pressure sensor. The pressure sensor in this case con-

sists of an etched diaphragm with some form of strain-sensing mechanism fabricated

on the top surface, as shown in Figure 4.8. This example assumes direct contact of

the pressurized media with the sensor chip, and therefore, other packaging require-

ments, such as oil filling, are not considered in this case. Pressure sensors are dis-

cussed in more detail in Chapter 6.

The simplest and lowest cost form of sensor package is to bond the sensor chip

directly to the second order packaging, in this a case a simple TO header as shown

schematically in Figure 4.9. Coupling to the sensor diaphragm is facilitated by a

pressure port formed in the header. Such an arrangement is based upon microelec-

tronic device packaging and effectively has no first order packaging stage. As a

result, mechanical stresses are transmitted directly to the sensor chip and the trans-

ducer housing is likely to be thermally incompatible with silicon due to TEC mis-

matches. The overall accuracy of the sensor will therefore be poor. Thermal stresses

can be compensated for to some degree by the sensing electronics, but associated

drift cannot be compensated for.

The above packaging solution is impractical in the vast majority of applications.

Improved mechanical isolation can be achieved by the following range of tech-

niques, the suitability of which will depend upon each application and its particular

packaging requirements:

• Use of a first order packaging stage (i.e., placing an intermediate, or support

chip, between the sensor chip and housing);

• Mechanical decoupling on the sensor or support chip;

• Displacing the sensor away from the second order packaging;

• Die attach using of soft ductile bond materials;

Pressure-sensing

diaphragm

Pressure

Figure 4.8 Typical pressure sensing die.