Page 84 - MEMS Mechanical Sensors

P. 84

4.4 MEMS Mechanical Sensor Packaging 73

Header cap

Wirebond

Pressure sensor die

TO header Die attach

Leadout

Pressure port

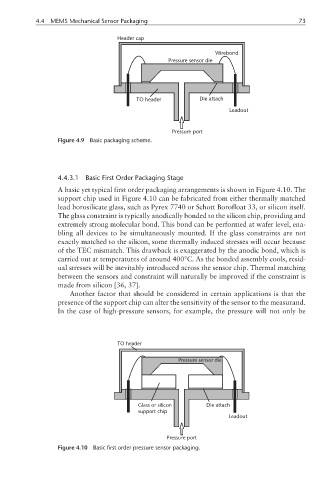

Figure 4.9 Basic packaging scheme.

4.4.3.1 Basic First Order Packaging Stage

A basic yet typical first order packaging arrangements is shown in Figure 4.10. The

support chip used in Figure 4.10 can be fabricated from either thermally matched

lead borosilicate glass, such as Pyrex 7740 or Schott Borofloat 33, or silicon itself.

The glass constraint is typically anodically bonded to the silicon chip, providing and

extremely strong molecular bond. This bond can be performed at wafer level, ena-

bling all devices to be simultaneously mounted. If the glass constraints are not

exactly matched to the silicon, some thermally induced stresses will occur because

of the TEC mismatch. This drawback is exaggerated by the anodic bond, which is

carried out at temperatures of around 400°C. As the bonded assembly cools, resid-

ual stresses will be inevitably introduced across the sensor chip. Thermal matching

between the sensors and constraint will naturally be improved if the constraint is

made from silicon [36, 37].

Another factor that should be considered in certain applications is that the

presence of the support chip can alter the sensitivity of the sensor to the measurand.

In the case of high-pressure sensors, for example, the pressure will not only be

TO header

Pressure sensor die

Glass or silicon Die attach

support chip

Leadout

Pressure port

Figure 4.10 Basic first order pressure sensor packaging.