Page 90 - MEMS Mechanical Sensors

P. 90

4.4 MEMS Mechanical Sensor Packaging 79

weight restrictions, the sensor was packaged alongside the electronics using an

MCM, as shown in Figure 4.16. The MCM incorporated epoxy-mounted ICs with

thick-film tracks, surface mount capacitors, and thick-film resistors. The sensor and

ICs were flush mounted to enable shorter wirebonds.

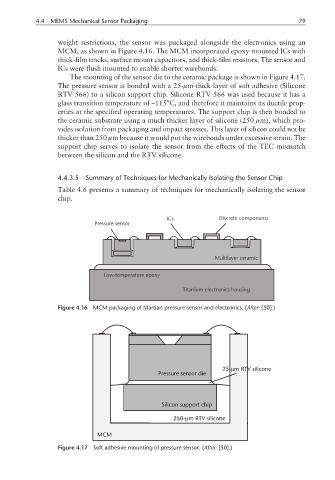

The mounting of the sensor die to the ceramic package is shown in Figure 4.17.

The pressure sensor is bonded with a 25-µm-thick layer of soft adhesive (Silicone

RTV 566) to a silicon support chip. Silicone RTV 566 was used because it has a

glass transition temperature of –115°C, and therefore it maintains its ductile prop-

erties at the specified operating temperatures. The support chip is then bonded to

the ceramic substrate using a much thicker layer of silicone (250 µm), which pro-

vides isolation from packaging and impact stresses. This layer of silicon could not be

thicker than 250 µm because it would put the wirebonds under excessive strain. The

support chip serves to isolate the sensor from the effects of the TEC mismatch

between the silicon and the RTV silicone.

4.4.3.5 Summary of Techniques for Mechanically Isolating the Sensor Chip

Table 4.6 presents a summary of techniques for mechanically isolating the sensor

chip.

ICs Discrete components

Pressure sensor

Multilayer ceramic

Low-temperature epoxy

Titanium electronics housing

Figure 4.16 MCM packaging of Martian pressure sensor and electronics. (After: [50].)

µ

25- m RTV silicone

Pressure sensor die

Silicon support chip

µ

250- m RTV silicone

MCM

Figure 4.17 Soft adhesive mounting of pressure sensor. (After: [50].)