Page 97 - MEMS Mechanical Sensors

P. 97

86 Mechanical Transduction Techniques

The sensitivity of a strain gauge is generally termed the gauge factor. This is a

dimensionless quantity and is given by

relative change in resistance ∆ / ∆ RR

RR

/

GF = = = (5.1)

applied strain ∆ R / L ε

where R is the initial resistance of the strain gauge and ∆R is the change in resistance.

The term ∆L/L is, by definition, the applied strain and is denoted as ε (dimension-

2

less). For all elastic materials, there is a relationship between the stress σ(N/m ) and

the strain ε; that is, they obey Hooke’s law and thus deform linearly with applied

force. The constant of proportionality is the elastic modulus or Young’s modulus of

the material and is given by

Stress σ

Young’s modulus, E = = (Nm 2 ) (5.2)

Strain ε

2

The Young’s modulus of silicon is 190 GPa (1 Pa=1N/m ), which is close to

that of typical stainless steel (around 200 GPa). For a given material, the higher the

value of Young’s modulus, the less it deforms for a given applied stress (i.e., it is

stiffer).

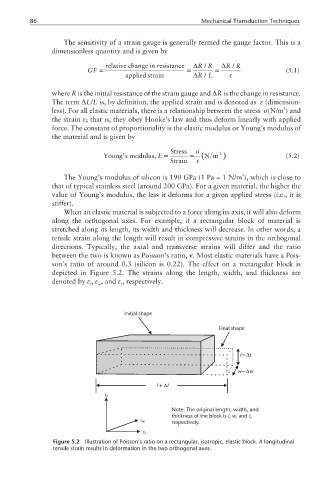

When an elastic material is subjected to a force along its axis, it will also deform

along the orthogonal axes. For example, if a rectangular block of material is

stretched along its length, its width and thickness will decrease. In other words, a

tensile strain along the length will result in compressive strains in the orthogonal

directions. Typically, the axial and transverse strains will differ and the ratio

between the two is known as Poisson’s ratio, ν. Most elastic materials have a Pois-

son’s ratio of around 0.3 (silicon is 0.22). The effect on a rectangular block is

depicted in Figure 5.2. The strains along the length, width, and thickness are

denoted by ε, ε , and ε , respectively.

l w t

Initial shape

Final shape

t−∆ t

w−∆ w

l + ∆ l

ε t

Note: The original length, width, and

thickness of the block is ,lw, and t,

ε w respectively.

ε l

Figure 5.2 Illustration of Poisson’s ratio on a rectangular, isotropic, elastic block. A longitudinal

tensile strain results in deformation in the two orthogonal axes.