Page 163 - Machinery Component Maintenance

P. 163

146 Machinery Component Maintenance and Repair

Primary Causes of Flange Leakage

Several common causes of flange leakage are hereby outlined to create

an awareness of the effects of poor inspection procedure or materials:

Uneven Bolt Stress., Flanges bolted up unevenly cause some bolts to be

nearly loose while others are so heavily loaded that they locally crush the

gasket. This causes leaks, particularly in high-temperature service where

the heavily-loaded bolts tend to relax with subsequent loosening of the

joint.

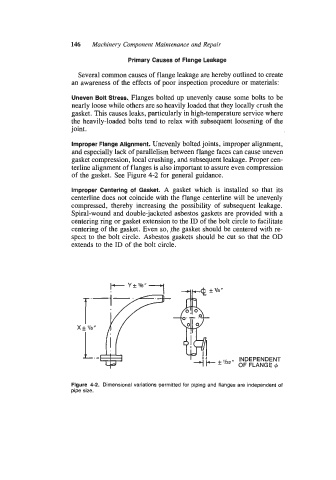

Improper Flange Alignment. Unevenly bolted joints, improper alignment,

and especially lack of parallelism between flange faces can cause uneven

gasket compression, local crushing, and subsequent leakage. Proper cen-

terline alignment of flanges is also important to assure even compression

of the gasket. See Figure 4-2 for general guidance.

Improper Centering of Gasket. A gasket which is installed so that its

centerline does not coincide with the flange centerline will be unevenly

compressed, thereby increasing the possibility of subsequent leakage.

Spiral-wound and double-jacketed asbestos gaskets are provided with a

centering ring or gasket extension to the ID of the bolt circle to facilitate

centering of the gasket. Even so, ,the gasket should be centered with re-

spcct to the bolt circlc. Asbestos gaskets should be cut so that the OD

extends to the ID of the bolt circle.

’I8 “

-* INDEPENDENT

’132

OF FLANGE 4

Figure 4-2. Dimensional variations permitted for piping and flanges are independent of

pipe size.