Page 160 - Machinery Component Maintenance

P. 160

Procc~ss Muchinet-! Pipiiig 143

Establishment of acceptable layout between terminal points for the

pipe.

Establishment of acceptable support configuration for the system.

Flexibility stress analysis for the system to satisfy the design criteria

stipulated by ANSI B3 1.3.

This flexibility analysis is intended to verify that piping stresses, local

component stresses and forcedmoments generated at the terminal points

are within the acceptable limits throughout all anticipated phases of nor-

inal and abnormal operation of the plant during its life.

Design Considerations

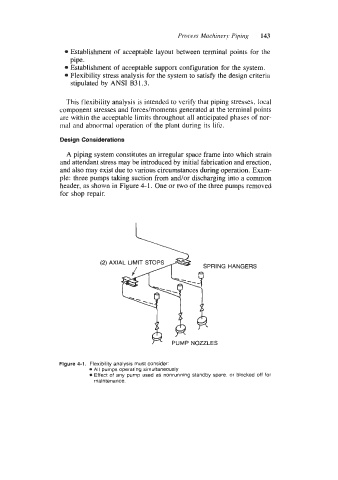

A piping system constitutes an irregular space frame into which strain

and attendant stress may be introduced by initial fabrication and erection,

and also may exist due to various circumstances during operation. Exam-

ple: three pumps taking suction from and/or discharging into a common

header, as shown in Figure 4-1. One or two of the three pumps removed

for shop repair.

HANGERS

Figure 4-1. Flexibility analysis must consider:

All pumps operating simultaneously

Effect of any pump used as nonrunning standby spare. or blocked off for

maintenance.