Page 417 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 417

Section 16.5 Bending Sheets, Plates, and Tubes 397

thick blank may not bend as easily around small radii Without cracking (as

described in Section 16.5 on bending). Friction and lubrication at the interface

between the punch and the sheet metal are also important factors in the test

results. With Well-lubricated interfaces, the strains in the sheet are distributed

more uniformly over the punch. Also, as expected, and depending on the material

and its notch sensitivity, surface scratches, deep gouges, and blemishes can reduce

formability significantly and thereby lead to premature tearing and failure of

the part.

l6.5 Bending Sheets, Plates, and Tubes

Bending is one of the most common industrial forming operations. We merely have

to look at an automobile body, appliance, paper clip, or file cabinet to appreciate

how many parts are shaped by bending. Furthermore, bending also imparts stiffness

to the part by increasing its moment of inertia. Note, for example, how corrugations,

flanges, beads, and seams improve the stiffness of structures With-

out adding any Wei ht. As a s ecific exam le, observe the diame- Bend

tral stiffness of a megfal can with and vvithotii circumferential beads auowance’ Lb Bend Iength’ L

(see also beading). Setback

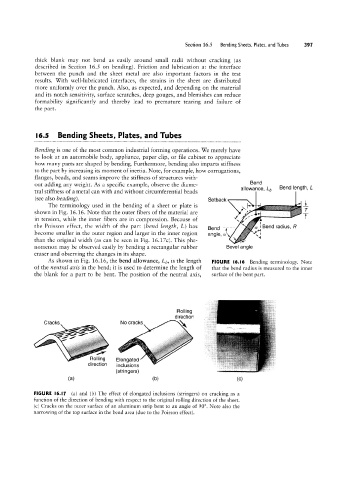

The terminology used in the bending of a sheet or plate is V 'L

,’

shovvn in Fig. 16.16. Note that the outer fibers of the material are T

in tension, while the inner fibers are in compression. Because of \ I gg, T T

Bend ____

the Poisson effect, the Width of the part (bend length, L) has :Bend radius, Fl

become smaller in the outer region and larger in the inner region angle, 0, (vi

than the original width (as can be seen in Fig. 16.17c). This phe- Q

nomenon may be observed easily by bending a rectangular rubber Bevel angle

eraser and observing the changes in its shape.

As shown in Fig. 16.16, the bend allowance, Lb, is the length |=|GuR5 |5_|5 Bending terminology Note

of the neutral axis in the bend; it is used to determine the length of that the bend radius is measured to the inner

the blank for a part to be bent. The position of the neutral axis, surface of the bent part.

\

Rolling

ffl direction

No cracks

Cracks :~

ff; ?? ._<' Fi?

é T @= ,; ijgs §;`,"§

f’i ROHWQ Elongated "Q,

direction inclusions "

(stringers)

(H) (D) (C)

FIGURE |6.l7 (a) and (b) The effect of elongated inclusions (stringers) on cracking as a

function of the direction of bending with respect to the original rolling direction of the sheet.

(c) Cracks on the outer surface of an aluminum strip bent to an angle of 9O°. Note also the

narrowing of the top surface in the bend area (due to the Poisson effect).