Page 420 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 420

00 Chapter 16 Sheet-Metal Forming Processes and Equipment

Pcounter

(3) (b) (C) (Ci)

aT‘==-_;r'm, Wk. ..., *gag*-_'Q

Sheet ' I

» f

Die Rocker l

2.

1. (G) 3.

de. . _

.==;¢¢

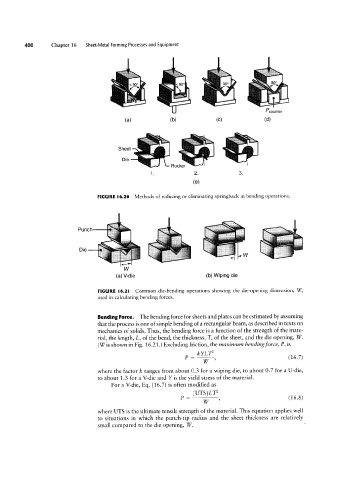

FIGURE I6.20 Methods of reducing or eliminating springback in bending operations.

Punch y

n°~‘

Die ,

mg

W vv

(a) V-die (b) Wiping die

FIGURE I6.2l Common die-bending operations showing the die-opening dimension, W,

used in calculating bending forces.

Bending Force. The bending force for sheets and plates can be estimated by assuming

that the process is one of simple bending of a rectangular beam, as described in texts on

mechanics of solids. Thus, the bending force is a function of the strength of the mate-

rial, the length, L, of the bend, the thickness, T, of the sheet, and the die opening, W.

(Wis shown in Fig. 16.21.) Excluding friction, the maximum bending force, P, is

/QYLTZ

W

P 1T , ( 16.7 l

Where the factor le ranges from about 0.3 for a Wiping die, to about 0.7 for a U-die,

to about 1.3 for a V-die and Y is the yield stress of the material.

For a V-die, Eq. (16.7) is often modified as

P _ (UTS)LT2 16 8

_ W a l ' )

Where UTS is the ultimate tensile strength of the material. This equation applies well

to situations in which the punch-tip radius and the sheet thickness are relatively

small compared to the die opening, W.