Page 424 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 424

04 Chapter 16 Sheet-Metal Forming Processes and Equipment

.gg ’» `.,,~.e

<a> rbi

FIGURE l6.26 (a) Schematic illustration of the roll-forming process. (b) Examples of roll-

formed cross sections. Source: (b) Courtesy of Sharon Custom Metal Forming, Inc.

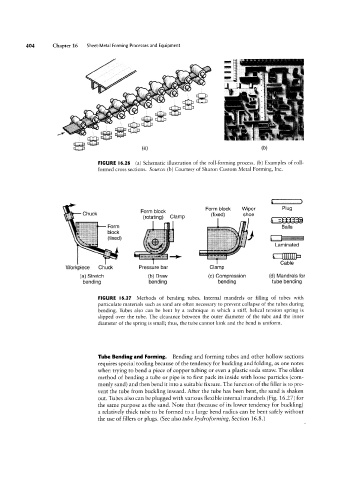

Form block Wiper Plug

F8L';E:;5k Champ (fixed) shoe

Chuck

Laminated

-> ‘W e gllllill-

C bl

Workpiece Chuck Pressure bar Clamp a e

(a) Stretch (b) Draw (c) Compression (d) I\/Iandrels for

bending bending bending tube bending

FIGURE l6.21 Methods of bending tubes. Internal mandrels or filling of tubes with

particulate materials such as sand are often necessary to prevent collapse of the tubes during

bending. Tubes also can be bent by a technique in which a stiff, helical tension spring is

slipped over the tube. The clearance between the outer diameter of the tube and the inner

diameter of the spring is small; thus, the tube cannot kink and the bend is uniform.

Tube Bending and Forming. Bending and forming tubes and other hollow sections

requires special tooling because of the tendency for buckling and folding, as one notes

when trying to bend a piece of copper tubing or even a plastic soda straw. The oldest

method of bending a tube or pipe is to first pack its inside with loose particles (com-

monly sand) and then bend it into a suitable fixture. The function of the filler is to pre-

vent the tube from buckling inward. After the tube has been bent, the sand is shaken

out. Tubes also can be plugged with various flexible internal mandrels (Fig. 1627) for

the same purpose as the sand. Note that (because of its lower tendency for buckling)

a relatively thick tube to be formed to a large bend radius can be bent safely without

the use of fillers or plugs. (See also tube /vydroforming, Section 16.8.)